Analytical Testing Instruments

-

YY-06A Soxhlet Extractor

Equipment Introduction:

Based on the Soxhlet extraction principle, the gravimetric method is adopted to determine the fat content in grains, cereals and foods. Comply with GB 5009.6-2016 “National Food Safety Standard – Determination of Fat in Foods”; GB/T 6433-2006 “Determination of Crude Fat in Feed” SN/T 0800.2-1999 “Inspection Methods for Crude Fat of Imported and Exported Grains and Feeds”

The product is equipped with an internal electronic refrigeration system, eliminating the need for an external water source. It also realizes the automatic addition of organic solvents, the addition of organic solvents during the extraction process, and the automatic recovery of solvents back into the solvent tank after the program is completed, achieving full automation throughout the entire process. It features stable performance and high accuracy, and is equipped with multiple automatic extraction modes such as Soxhlet extraction, hot extraction, Soxhlet hot extraction, continuous flow and standard hot extraction.

Equipment advantages:

Intuitive and convenient 7-inch color touch screen

The control screen is a 7-inch color touch screen. The back is magnetic and can be adhered to the surface of the instrument or removed for handheld operation. It features both automatic analysis and manual analysis modes

Menu-based program editing is intuitive, easy to operate, and can be looped in multiple times.

1)★ Patented technology “Built-in Electronic Refrigeration System”

It does not require an external water source, saves a large amount of tap water, has no chemical refrigerants, is energy-saving, environmentally friendly, and has a high extraction and reflux efficiency

2)★ Patented technology “Automatic Addition of Organic Solvents” system

A. Automatic addition volume: 5-150ml. Add in sequence through 6 solvent cups or add in A designated solvent cup

B. When the program runs to any node, solvents can be automatically added or manually added

3)★ Automatic collection and addition of organic solvents to the solvent tank device

At the end of the extraction process, the recovered organic solvent is automatically “collected into a metal container” for the next use

-

YY-06 Soxhlet Extractor

Equipment Introduction:

Based on the Soxhlet extraction principle, the gravimetric method is adopted to determine the fat content in grains, cereals and foods. Comply with GB 5009.6-2016 “National Food Safety Standard – Determination of Fat in Foods”; GB/T 6433-2006 “Determination of Crude Fat in Feed” SN/T 0800.2-1999 “Inspection Methods for Crude Fat of Imported and Exported Grains and Feeds”

The product is designed with fully automatic one-click operation, featuring simple operation, stable performance and high precision. It offers multiple automatic extraction modes such as Soxhlet extraction, hot extraction, Soxhlet hot extraction, continuous flow and standard hot extraction

Equipment advantages:

Intuitive and convenient 7-inch color touch screen

The control screen is a 7-inch color touch screen. The back is magnetic and can be adhered to the surface of the instrument or removed for handheld operation. It features both automatic analysis and manual analysis modes

Menu-based program editing is intuitive, easy to operate, and can be looped in multiple times

-

YY-06 Automatic Fiber Analyzer

Equipment Introduction:

The automatic fiber analyzer is an instrument that determines the crude fiber content of the sample by dissolving it with the commonly used acid and alkali digestion methods and then measuring its weight. It is applicable to the determination of crude fiber content in various grains, feeds, etc. The test results comply with the national standards. The determination objects include feeds, grains, cereals, foods and other agricultural and sideline products that need to have their crude fiber content determined

This product is an economical one, featuring a simple structure, easy operation and high cost performance.

Equipment advantages:

YY-06 Automatic Fiber Analyzer is a Simple and economical product, capable of processing 6 samples each time. The crucible heating is controlled by a temperature control instrument, and the reagent addition and suction filtration are controlled by a switch. The heating structure is simple, easy to operate and cost-effective

-

YY-20SX /20LX Digestive System

l Product Features:

1) This digestion system is designed with a curve heating digestion furnace as the main body, combined with exhaust gas collection and exhaust gas neutralization. It realizes the one-click completion of the sample processing process from ① sample digestion → ② exhaust gas collection → ③ exhaust gas neutralization treatment → ④ stop heating when digestion is completed → ⑤ separate the digestion tube from the heating body and cool down for standby. It achieves the automation of the sample digestion process, improves the working environment, and reduces the workload of the operators.

2) Test tube rack in-place detection: If the test tube rack is not placed or not placed properly, the system will alarm and not work, preventing equipment damage caused by running without samples or incorrect placement of test tubes.

3) Anti-pollution tray and alarm system: The anti-pollution tray can prevent acid liquid from the exhaust gas collection port from polluting the operation table or other environments. If the tray is not removed and the system is run, it will alarm and stop running.

4) The digestion furnace is a sample digestion and conversion equipment developed based on the classic wet digestion principle. It is mainly used in agriculture, forestry, environmental protection, geology, petroleum, chemical, food and other departments, as well as universities and research institutions for the digestion treatment of plant, seed, feed, soil, ore and other samples before chemical analysis. It is the best matching product for Kjeldahl nitrogen analyzers.

5) The S graphite heating module has good uniformity and small temperature buffering, with a designed temperature up to 550℃.

6) The L aluminum alloy heating module has fast heating, long service life, and wide application. The designed temperature is 450℃.

7) The temperature control system adopts a 5.6-inch color touch screen with Chinese-English conversion, and is simple to operate.

8) The formula program input adopts a table-based rapid input method, which is logical, fast, and less prone to errors.

9) 0-40 segments of programs can be freely selected and set.

10) Single-point heating and curve heating dual modes can be freely selected.

11) Intelligent P, I, D self-tuning ensures high, reliable and stable temperature control accuracy.

12) Segmented power supply and anti-power-off restart function can prevent potential risks from occurring.

13) Equipped with over-temperature, over-pressure and over-current protection modules.

-

YY-40 Fully Automatic Test Tube Cleaning Machine

- Brief Introduction

Due to the wide variety of laboratory vessels, especially the thin and long structure of large test tubes, it brings certain difficulties to the cleaning work. The automatic test tube cleaning machine developed by our company can automatically clean and dry the inside and outside of the test tubes in all aspects. It is particularly suitable for the cleaning of test tubes in Kjeldahl nitrogen determinators

- Product Features

1) 304 stainless steel vertical pipe spray, high-pressure water flow and large-flow pulse cleaning can ensure cleaning cleanliness.

2) High-pressure and large-airflow heating air-drying system can quickly complete the drying task, with the maximum temperature of 80℃.

3) Automatic addition of cleaning liquid.

4) Built-in water tank, automatic water replenishment and automatic stop.

5) Standard cleaning: ① Clear water spray → ② Spray cleaning agent foam → ③ Soak → ④ Clear water rinse → ⑤ High-pressure hot air drying.

6) Deep cleaning: ① Clear water spray → ② Spray cleaning agent foam → ③ Soak → ④ Clear water rinse → ⑤ Spray cleaning agent foam → ⑥ Soak → ⑦ Clear water rinse → ⑧ High-pressure hot air drying.

-

YY-20SX /20LX Digestive System

l Product Features:

1) This digestion system is designed with a curve heating digestion furnace as the main body, combined with exhaust gas collection and exhaust gas neutralization. It realizes the one-click completion of the sample processing process from ① sample digestion → ② exhaust gas collection → ③ exhaust gas neutralization treatment → ④ stop heating when digestion is completed → ⑤ separate the digestion tube from the heating body and cool down for standby. It achieves the automation of the sample digestion process, improves the working environment, and reduces the workload of the operators.

2) Test tube rack in-place detection: If the test tube rack is not placed or not placed properly, the system will alarm and not work, preventing equipment damage caused by running without samples or incorrect placement of test tubes.

3) Anti-pollution tray and alarm system: The anti-pollution tray can prevent acid liquid from the exhaust gas collection port from polluting the operation table or other environments. If the tray is not removed and the system is run, it will alarm and stop running.

4) The digestion furnace is a sample digestion and conversion equipment developed based on the classic wet digestion principle. It is mainly used in agriculture, forestry, environmental protection, geology, petroleum, chemical, food and other departments, as well as universities and research institutions for the digestion treatment of plant, seed, feed, soil, ore and other samples before chemical analysis. It is the best matching product for Kjeldahl nitrogen analyzers.

5) The S graphite heating module has good uniformity and small temperature buffering, with a designed temperature up to 550℃.

6) The L aluminum alloy heating module has fast heating, long service life, and wide application. The designed temperature is 450℃.

7) The temperature control system adopts a 5.6-inch color touch screen with Chinese-English conversion, and is simple to operate.

8) The formula program input adopts a table-based rapid input method, which is logical, fast, and less prone to errors.

9) 0-40 segments of programs can be freely selected and set.

10) Single-point heating and curve heating dual modes can be freely selected.

11) Intelligent P, I, D self-tuning ensures high, reliable and stable temperature control accuracy.

12) Segmented power supply and anti-power-off restart function can prevent potential risks from occurring.

13) Equipped with over-temperature, over-pressure and over-current protection modules.

l Waste gas collection device

1.The sealing cover is made of polytetrafluoroethylene, which is heat-resistant and resistant to strong acids and alkalis

2. It is designed as a conical structure with a flat cover, and each sealed cover weighs 35g

3. The sealing method adopts gravity natural sealing, which is reliable and convenient

4. The collection pipe extends deep into the pipe to collect acid gas, ensuring high reliability

5. The shell is welded with 316 stainless steel plates and has good anti-corrosion performance.

l Neutralization device

1.This product is an acid and alkali neutralization device with a built-in negative pressure air pump. The air pump features a large flow rate, long service life and easy operation.

2.The three-stage absorption of alkali solution, distilled water and gas ensures the reliability of the discharged gas

3.The instrument is simple, safe and reliable to use

-

YY-06A Automatic Soxhlet Extractor

Equipment Introduction:

Based on the Soxhlet extraction principle, the gravimetric method is adopted to determine the fat content in grains, cereals and foods. Comply with GB 5009.6-2016 “National Food Safety Standard – Determination of Fat in Foods”; GB/T 6433-2006 “Determination of Crude Fat in Feed” SN/T 0800.2-1999 “Inspection Methods for Crude Fat of Imported and Exported Grains and Feeds”

The product is equipped with an internal electronic refrigeration system, eliminating the need for an external water source. It also realizes the automatic addition of organic solvents, the addition of organic solvents during the extraction process, and the automatic recovery of solvents back into the solvent tank after the program is completed, achieving full automation throughout the entire process. It features stable performance and high accuracy, and is equipped with multiple automatic extraction modes such as Soxhlet extraction, hot extraction, Soxhlet hot extraction, continuous flow and standard hot extraction.

-

YY-06 Soxhlet Extractor

Equipment Introduction:

Based on the Soxhlet extraction principle, the gravimetric method is adopted to determine the fat content in grains, cereals and foods. Comply with GB 5009.6-2016 “National Food Safety Standard – Determination of Fat in Foods”; GB/T 6433-2006 “Determination of Crude Fat in Feed” SN/T 0800.2-1999 “Inspection Methods for Crude Fat of Imported and Exported Grains and Feeds”

The product is designed with fully automatic one-click operation, featuring simple operation, stable performance and high precision. It offers multiple automatic extraction modes such as Soxhlet extraction, hot extraction, Soxhlet hot extraction, continuous flow and standard hot extraction.

-

YY-06 Fiber Analyzer

Equipment Introduction:

The automatic fiber analyzer is an instrument that determines the crude fiber content of the sample by dissolving it with the commonly used acid and alkali digestion methods and then measuring its weight. It is applicable to the determination of crude fiber content in various grains, feeds, etc. The test results comply with the national standards. The determination objects include feeds, grains, cereals, foods and other agricultural and sideline products that need to have their crude fiber content determined

This product is an economical one, featuring a simple structure, easy operation and high cost performance.

-

YY-KND200 Automatic Kjeldahl Nitrogen Analyzer

- Product Introduction:

Kjeldahl method is a classical method for nitrogen determination. Kjeldahl method is widely used to determine nitrogen compounds in soil, food, animal husbandry, agricultural products, feed and other materials. The sample determination by Kjeldahl method requires three processes: sample digestion, distillation separation and titration analysis

YY-KDN200 automatic Kjeldahl nitrogen analyzer is based on classic Kjeldahl nitrogen determination method developed sample automatic distillation, automatic separation and analysis of “nitrogen element” (protein) through external related technology analysis system, its method, manufacturing in line with the “GB/T 33862-2017 full (half) automatic Kjeldahl nitrogen analyzer” manufacturing standards and international standards.

-

YY-700IIA2-EP Biological Safety Cabinet(desktop)

Product Features:

1. Air curtain isolation design to prevent cross-contamination between the inside and outside. 30% of the air is discharged and 70% is recirculated. Negative pressure vertical laminar flow without the need for installation of pipes.

2. Up and down sliding glass doors that can be positioned freely, easy to operate, and can be fully closed for sterilization. Height limit alarm prompt for positioning.

3. Power output sockets in the working area, equipped with waterproof sockets and drainage interfaces, providing great convenience for operators.

4. Special filters are installed at the exhaust outlet to control emissions and pollution.

5. The working environment is free from pollution leakage. Made of high-quality 304 stainless steel, it is smooth, seamless, and has no dead corners, making it easy to disinfect thoroughly and resistant to corrosion and disinfectant erosion.

6. Controlled by an LED liquid crystal panel, with an internal UV lamp protection device. The UV lamp can only operate when the front window and fluorescent lamp are turned off, and it has a UV lamp timing function.

7. 10° tilt angle, in line with ergonomic design.

-

YY-B2 Series Biosafety Cabinet

Product Characteristics

1. Air curtain isolation design prevents internal and external cross contamination, with 100% air flow discharged, negative pressure vertical flow, and no need to install pipelines.

2. The front glass can be moved up and down allows for arbitrary positioning which is easy to operate, and complete closure for sterilization. The positioning height limit alarm prompts.

3. The power output socket in the work area is equipped with waterproof sockets and sewage outlets, providing great convenience for operators

4. HEPA filter is installed at the exhaust area to control emission pollution

5. The working area is made of high-quality 304 stainless steel, which is smooth, seamless, and has no dead corners. It can be easily and thoroughly disinfected to prevent corrosion and disinfectant erosion.

6. Controlled by an LCD panel with built-in UV light protection device, it can only be opened when the safety door is closed.

7. Equipped with DOP test port and built-in differential pressure gauge.

8. 10 ° inclination angle, in line with human body design concepts.

-

YY-A2 Series Biological Safety Cabinet

Product Features:

1. Air curtain isolation design to prevent cross-contamination between the inside and outside. 30% of the air is discharged and 70% is recirculated. Negative pressure vertical laminar flow without the need for installation of pipes.

2. Up and down sliding glass doors that can be positioned freely, easy to operate, and can be fully closed for sterilization. Height limit alarm prompt for positioning.

3. Power output sockets in the working area, equipped with waterproof sockets and drainage interfaces, providing great convenience for operators.

4. Special filters are installed at the exhaust outlet to control emissions and pollution.

5. The working environment is free from pollution leakage. Made of high-quality 304 stainless steel, it is smooth, seamless, and has no dead corners, making it easy to disinfect thoroughly and resistant to corrosion and disinfectant erosion.

6. Controlled by an LED liquid crystal panel, with an internal UV lamp protection device. The UV lamp can only operate when the front window and fluorescent lamp are turned off, and it has a UV lamp timing function.

7. 10° tilt angle, in line with ergonomic design.

-

YYQL-E 0.01mg Electronic analytical balance

Summary:

YYQL-E series electronic analytical balance adopts internationally recognized high sensitivity, high stability rear electromagnetic force sensor technology, leading the industry similar products in the level of cost performance, innovative appearance, to win higher product pricing initiative, the whole machine texture, rigorous technology, exquisite.

Products are widely used in scientific research, education, medical, metallurgy, agriculture and other industries.

Product highlights:

· Rear electromagnetic force sensor

· Fully transparent glass wind shield, 100% visible to samples

· Standard RS232 communication port to realize the communication between data and computer, printer or other equipment

· Stretchable LCD display, avoiding the impact and vibration of the balance when the user operates the keys

* Optional weighing device with lower hook

* Built-in weight one button calibration

* Optional thermal printer

Fill weighing function Percentage weighing funion

Piece weighing function Bottom weighing function

-

YY-RO-C2 Radio Frequency Identification Water Purification System.

- Application:

GC, HPLC, IC, ICP, PCR application and analysis, meteorological analysis, precision instrument analysis, amino acid analysis, analytical reagents and drug configuration, dilution, etc.

- Water intake requirement:

Urban tap water (TDS<250ppm, 5-45℃, 0.02-0.25Mpa, pH3-10).

- System Process–PP+UDF+PP+RO+DI

First process —–One inch PP filter (5 MICRON)

Scond process——-Integrated granular activated carbon filter (coconut shell carbon)

Third process——Integrated PP Filter (1MICRON)

Forth process—–100GPD RO membrane

Fifth process——-Ultra purified column (nuclear grade mixed bed resin)×4

- Technical Parameter:

1.System water yield (25℃) :15 liters/hour

2.Maximum yield of ultra-pure water (25℃) : 1.5 L/min (open pressure storage tank)

3.Maximum yield of reverse osmosis water: 2 L/min (open pressure storage tank)

UP ultra-pure water index:

- Resistivity: 18.25MΩ.cm@25℃

- Conductivity: 0.054us/cm@25℃(< 0.1us/cm)

- Heavy metal ion (ppb) : <0.1ppb

- Total organic carbon (TOC) : <5ppb

- Bacteria: <0.1cfu/ml

- Microbial/bacterial: <0.1CFU/ml

- Particulate matter (>0.2μm) : <1/ml

RO reverse osmosis water index:

1.TDS(total solid solubility,ppm) : ≤ influent TDS×5%(stable desalting rate ≥95%)

2.Divalent ion separation rate: 95%-99%(when using the new RO membrane).

3.Organic separation rate: >99%, when MW>200Dalton

4.Front outlet: RO reverse osmosis outlet, UP ultra-pure outlet

5.Side outlet: water inlet, waste water outlet, water tank outlet

6.Digital water quality monitoring: LCD on-line resistivity, conductivity

7.Dimensions/weight: Length × width × height: 35×36×42cm

8.Power/Power: AC220V±10%,50Hz; 120W

-

YYJ Waste Gas Collection Device

I.Introductions:

The collection device is specially designed for the digestion furnace acid gas collection device,

which can collect a large amount of acid gas (acid mist) generated during the sample digestion

process through the collection device, and then through the negative pressure device or

neutralization device for treatment.

-

YY-1B Acid & Base Neutralization Device

I.Introduction:

The sample digestion process will produce a lot of acid fog, which will cause serious pollution

to the environment and damage the facilities. This device is the best instrument for collecting,

neutralizing and filtering acid fog. It consists of three filters. The first stage is neutralized and filtered

by the corresponding concentration of alkali solution into the second stage, and the second

stage uses distilled water to continue to filter the residual waste gas entering the first stage into

the third stage buffer, and the gas after the third stage filtration can be discharged according

to the standard without causing harm to the environment and facilities, and finally achieve

pollution-free emission

-

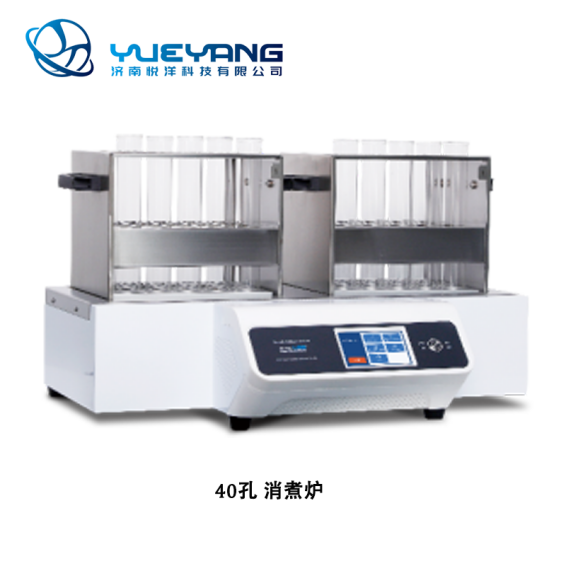

YYD-S Curve Heating Graphite Digester 40 holes

I.Introduction:

Digestion furnace is a sample digestion and conversion equipment developed on the basis of

classical wet digestion principle. It is mainly used in agriculture, forestry, environmental protection, geology, petroleum, chemical industry, food and other departments as well as universities and

scientific research departments for the digestion treatment of plants, seeds, feed, soil, ore and

other samples before chemical analysis, and is the best supporting product of Kjeldahl nitrogen analyzer.

II.Product Features:

1. The heating body adopts high-density graphite, infrared radiation technology, good uniformity,

small temperature buffer, design temperature 550℃

2. The temperature control system uses a 5.6-inch color touch screen, which can be converted into Chinese and English, and the operation is simple

3. Formula program input using the form of fast input method, clear logic, fast speed, not easy to mistake

4.0-40 segment program can be arbitrarily selected and set

5. Single point heating, curve heating dual mode optional

6. Intelligent P, I, D self-tuning temperature control high precision, reliable and stable

7. The electric control system uses solid-state relay, which is quiet and has strong anti-interference ability.

8. Segmented power supply and anti-power failure restart function can avoid potential risks. It is equipped with over-temperature, over-voltage and over-current protection modules

9.40 hole cooking furnace is the best supporting product of 8900 automatic Kjeldahl nitrogen

analyzer

-

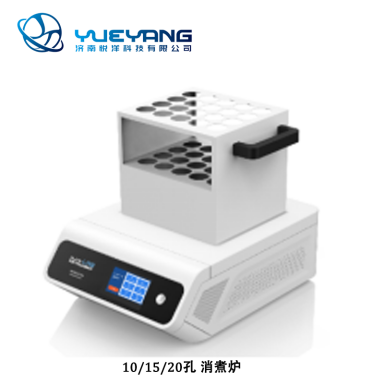

YYD-S Curve Heating Graphite Digester

I.Introduction:

Digestion furnace is a sample digestion and conversion equipment developed on the basis of

classical wet digestion principle. It is mainly used in agriculture, forestry, environmental protection, geology, petroleum, chemical industry, food and other departments as well as universities and

scientific research departments for the digestion treatment of plants, seeds, feed, soil, ore and

other samples before chemical analysis, and is the best supporting product of Kjeldahl nitrogen analyzer.

II.Product Features:

1. The heating body adopts high-density graphite, infrared radiation technology, good uniformity,

small temperature buffer, design temperature 550℃

2. The temperature control system uses a 5.6-inch color touch screen, which can be converted into Chinese and English, and the operation is simple

3. Formula program input using the form of fast input method, clear logic, fast speed, not easy to mistake

4.0-40 segment program can be arbitrarily selected and set

5. Single point heating, curve heating dual mode optional

6. Intelligent P, I, D self-tuning temperature control high precision, reliable and stable

7. The electric control system uses solid-state relay, which is quiet and has strong anti-interference ability.

8. Segmented power supply and anti-power failure restart function can avoid potential risks. It is equipped with over-temperature, over-voltage and over-current protection modules

9.40 hole cooking furnace is the best supporting product of 8900 automatic Kjeldahl nitrogen

analyzer.

-

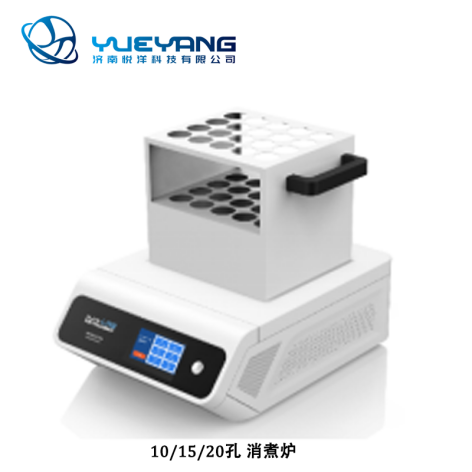

YYD-L Curve Temperature Aluminum Ingot Digester

I.Introduction:

Digestion furnace is a sample digestion and conversion equipment developed on the basis of

classical wet digestion principle. It is mainly used in agriculture, forestry, environmental protection,

geology, petroleum, chemical industry, food and other departments as well as universities and

scientific research departments for the digestion treatment of plants, seeds, feed, soil, ore and

other samples before chemical analysis, and is the best supporting product of Kjeldahl nitrogen

analyzer.