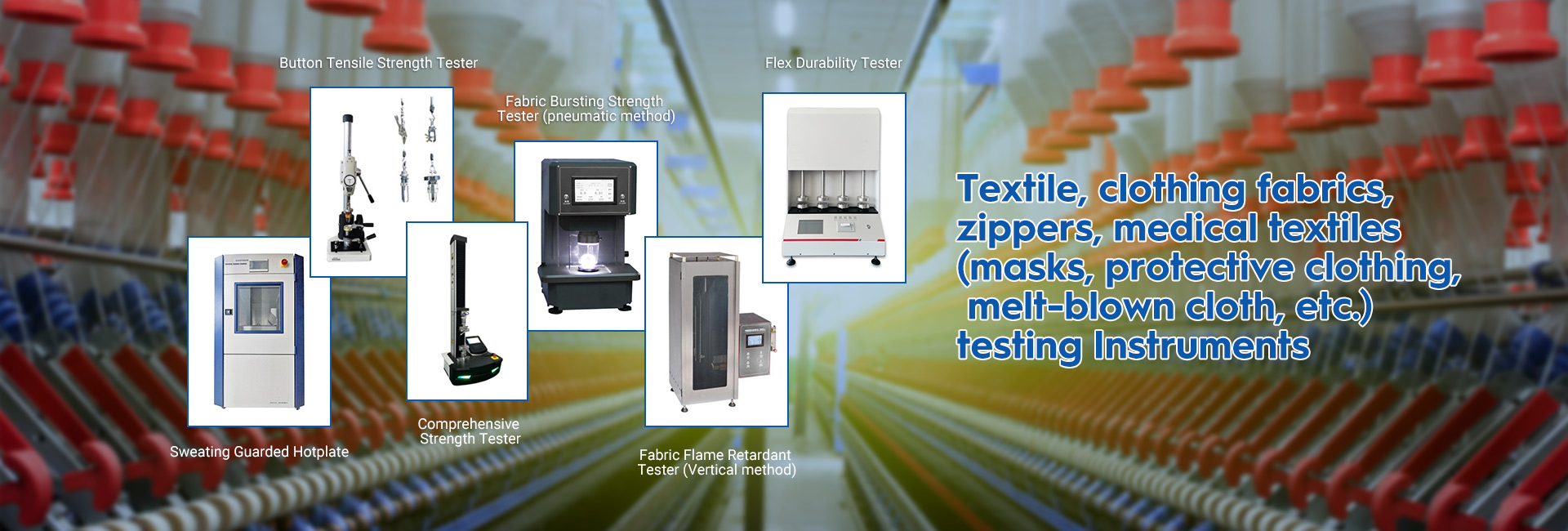

Environmental test chamber

-

YYP 50L Constant Temperature&Humidity Chamber

Meeting standard:

The performance indicators meet the requirements of GB5170, 2, 3, 5, 6-95 “Basic parameter Verification method of environmental test equipment for electrical and electronic products Low temperature, high temperature, constant wet heat, alternating wet heat test equipment”

Basic environmental test procedures for electrical and electronic products Test A: Low temperature

test method GB 2423.1-89 (IEC68-2-1)

Basic environmental test procedures for electrical and electronic products Test B: High temperature

test method GB 2423.2-89 (IEC68-2-2)

Basic environmental test procedures for electrical and electronic products Test Ca: Constant wet

heat test method GB/T 2423.3-93 (IEC68-2-3)

Basic environmental test procedures for electrical and electronic products Test Da: Alternating

humidity and heat test method GB/T423.4-93(IEC68-2-30)

-

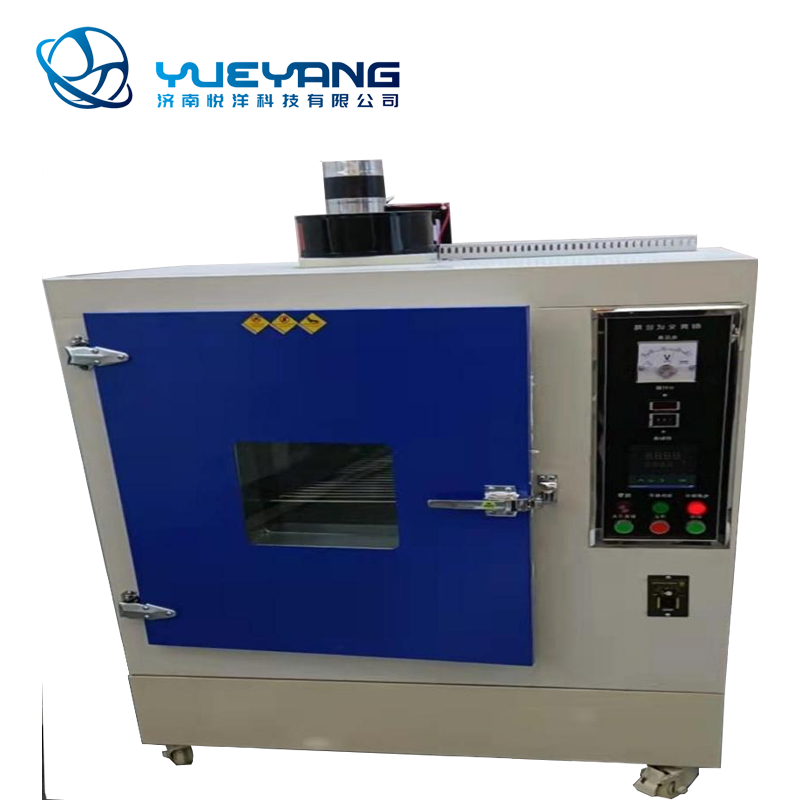

YY NH225 Yellowing Resistance Aging Oven

Summary:

It is manufactured in accordance with ASTM D1148 GB/T2454HG/T 3689-2001, and its function

is to simulate the ultraviolet radiation and heat of sunlight. The sample is exposed to ultraviolet

radiation and temperature in the machine, and after a period of time, the degree of yellowing

resistance of the sample is observed. The staining gray label can be used as a reference to

determine the grade of yellowing. The product is affected by sunlight radiation during use or the

influence of the container environment during transportation, resulting in the color change of the

product.

-

YYS Series Biochemical Incubator

Structure

The biochemical incubator of this series consists of a cabinet, a temperature control device,

a heating refrigeration system, and a circulating air duct. The box chamber is made of mirror

stainless steel, surrounded by circular arc structure, easy to clean. The case shell is sprayed

with high quality steel surface. The box door is equipped with an observation window, which is convenient for observing the state of the test products in the box. The height of the screen can

be adjusted arbitrarily.

The heat insulation property of the polyurethane foam board between the workshop and the box

is good, and the insulation performance is good. The temperature control device mainly consists

of a temperature controller and a temperature sensor. The temperature controller has the functions

of over-temperature protection, timing and power-off protection. The heating and refrigeration system

is composed of heating tube, evaporator, condenser and compressor. Gas circulating air duct, this series of biochemical box circulating air duct design is reasonable, to maximize the temperature uniformity in the box. The biochemical box is equipped with a lighting device to facilitate users to observe objects in the box.

-

YY-800C/ CH Constant Temperature&Humidity Chamber

Major dispositions:

1.Temperature range: A: -20°C to 150 °C B: -40 °C to 150 °C C: -70-150°C

2.Humidity range: 10% relative humidity to 98% relative humidity

3.Display instrument: 7-inch TFT color LCD display (RMCS control software)

4.Operation mode: fixed value mode, program mode (preset 100 sets 100 steps 999 cycles)

5.Control mode: BTC balance temperature control mode + DCC (intelligent cooling

control) + DEC (intelligent electrical control) (temperature test equipment)

BTHC balance temperature and humidity control control mode + DCC (intelligent cooling control) + DEC (intelligent electrical control) (temperature and humidity test equipment)

6.Curve recording function: RAM with battery protection can save the equipment

Set value, sampling value and sampling time; the maximum recording time is 350

days (when the sampling period is 1 / min).

7.Software usage environment: the upper computer operating software is

compatible with XP, Win7, Win8, Win10 operating system (user-provided)

8.Communication function: RS-485 interface MODBUS RTU communication

protocol,

9.Ethernet interface TCP / IP communication protocol two option; support

secondary development Provide upper computer operation software, RS-485 interface single device link, Ethernet interface can realize remote communication of multiple devices.

10.Working mode: A / B: mechanical single stage compression refrigeration system C: double stage stack compressor refrigeration mode

11.Observation mode: heated observation window with LED internal lighting

12.Temperature and humidity sensing mode: temperature: Class A PT 100 armoured thermocouple

13.Humidity: Class A type PT 100 armoured thermocouple

14.Dry and wet bulb thermometer (only during humidity controlled tests)

15.Safety protection: fault alarm and cause, processing prompt function, power off protection function, upper and lower limit temperature protection function, calendar timing function (automatic start and automatic stop operation), self-diagnosis function

16.Verification configuration: Access hole with silicone plug (50 mm, 80mm, 100mm left)

Data interface: Ethernet + software, USB data export, 0-40MA signal output

-

YYP643 Salt Spray Corrosion Test Chamber

YYP643 Salt spray corrosion test chamber with latest PID control is widely

used in

salt spray corrosion test of electroplated parts, paints, coatings, automobile

and motorcycle parts, aviation and military parts, protective layers of metal

materials,

and industrial products such as electric and electronic systems.

-

YYS-150 High & low Temperature Humid Heat Alternating Test Chamber

1.Stainless steel 316L finned heat dissipating heat pipe electric heater.

2.Control mode: PID control mode, using non-contact and other periodic pulse broadening SSR (solid state relay)

3.TEMI-580 True Color Touch programmable Temperature and Humidity controller

4.Program control 30 groups of 100 segments (the number of segments can be arbitrarily adjusted and allocated to each group)

-

YYS-1200 Rain Test Chamber

Function overview:

1. Carry out rain test on the material

2. Equipment standard: Meet the standard GB/T4208, IPX0 ~ IPX6, GB2423.38, GJB150.8A test requirements.

-

YY-CY Ozone Aging Test Chamber

Control System:

1. The original imported Japanese Panasonic PLC, ozone concentration controller, matched with the British imported ozone concentration sensor, can accurately detect and control the ozone concentration, and can control the ozone concentration deviation to ≤5% (the national standard requires ≤10%);

2. Temperature controller: Panasonic PLC, human-machine touch screen adopts Taiwan Weinview;

3. Temperature sensor: PT100 platinum resistance temperature tester;

4. Control method: thermal balance temperature adjustment method;

5. Electrical control components: “Schneider” and “Omron” components are used to better control the temperature, refer to the picture.

-

YY646 Xenon Lamp Aging Test Chamber

Detailed specifications

▶Model: YY 646

▶Studio size: D350*W500*H350mm

▶Sample tray size: 450*300mm (effective irradiation area)

▶Temperature range: normal temperature~80℃ adjustable

▶Humidity range: 50~95% R•H adjustable

▶Blackboard temperature: 40~80℃ ±3℃

▶Temperature fluctuation: ±0.5℃

▶Temperature uniformity: ±2.0℃

▶Filter: 1 piece (glass window filter or quartz glass filter according to customer needs)

▶Xenon lamp source: air-cooled lamp

▶Number of xenon lamps: 1

▶Xenon lamp power: 1.8 KW/each

▶Heating power: 1.0KW

▶ Humidification power: 1.0KW

▶ Distance between sample holder and lamp: 230~280mm (adjustable)

▶Xenon lamp wavelength: 290~800nm

▶The light cycle is continuously adjustable, time: 1~999h, m, s

▶Equipped with radiometer: 1 UV340 radiometer, the narrow-band irradiance is 0.51W/㎡;

▶Irradiance: The average irradiance between the wavelengths of 290nm and 800nm is 550W/㎡;

▶The irradiance can be set and automatically adjusted;

▶Automatic spray device;

-

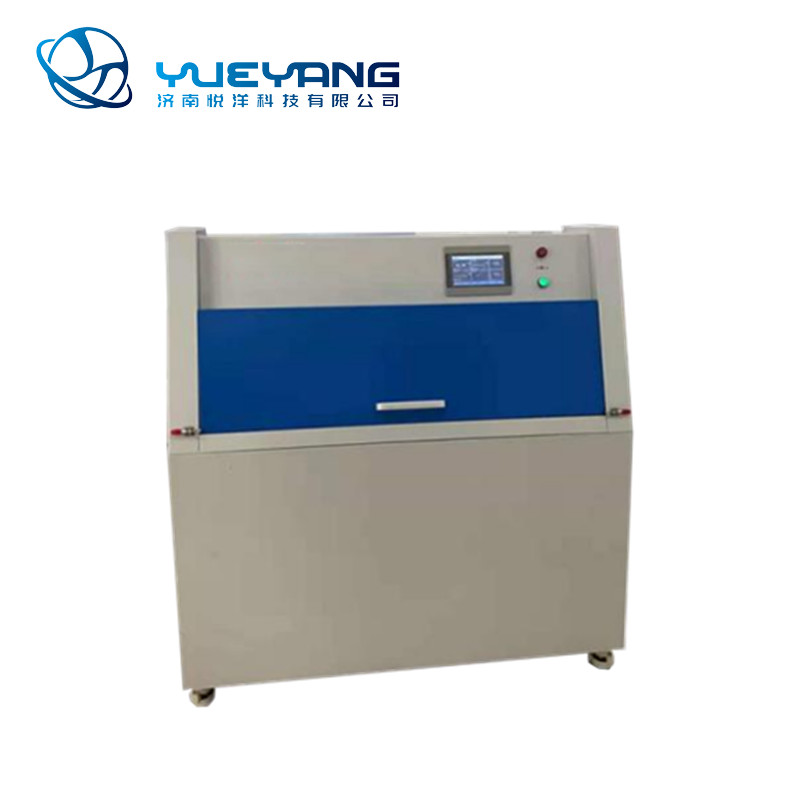

YY-300 UV Weathering Test Chamber

Compliant with international testing standards:

ASTM G 153, ASTM G 154, ASTM D 4329, ASTM D 4799, ASTM D 4587, SAEJ2020, ISO 4892 All current UV aging test standards.

Technical parameter:

1.Studio size: mm (D×W×H) 450×1170×500

2.Dimensions: mm (D×W×H) 600×1310×1350

3.Center distance of lamp: 70mm

4.The distance between the specimen and the nearest parallel surface of the lamp surface: about 50mm

5.Wavelength range: UV-A wavelength range is 315~400nm

6.Radiation intensity: 1.5W/m2/340nm

7.Temperature Resolution: 0.1℃

8.Lighting temperature range: 50℃~70℃/temperature tolerance is ±3℃

9.Condensing temperature range: 40℃~60℃/temperature tolerance is ±3℃

10.Black panel thermometer measuring range: 30~80℃/tolerance is ±1℃

11.Temperature control method: PID self-tuning temperature control method

12.Humidity range: about 45%~70%R.H (light state)/98% or more (condensation state)

13.Sink requirements: the water depth is not more than 25mm, and there is an automatic water supply controller

14.Standard specimen size: 75×150mm 48pcs

15.Recommended use environment for the instrument: 5~35℃, 40%~85%R·H, 300mm away from the wall

-

YYS-100 Constant Temperature&Humidity Chamber(0℃)

I.Summary: Instruments Name Programmable constant temperature & humidity test chamber Model No: YYS-100 Internal studio dimensions(D*W*H) 400×450×550mm Overall dimension(D*W*H) 9300×9300×1500mm Instruments structure Single-chamber vertical Technical parameter Temperature range 0℃~+150℃ Single stage refrigeration Temperature fluctuation ≤±0.5℃ Temperature uniformity ≤2℃ Cooling rate 0.7~1℃/min(average) Heating rate 3~5℃/min(average) Humidity range 10%-98%R... -

YYS-250 Constant Temperature&Humidity Chamber(-40℃)

I.Summary: Instruments Name Programmable constant temperature & humidity test chamber Model No: YYS-250 Internal studio dimensions(W*H*D) 460*720*720mm Overall dimension(W*H*D) 1100*1900*1300mm Instruments structure Single-chamber vertical Technical parameter Temperature range -40℃~+150℃ Single stage refrigeration Temperature fluctuation ≤±0.5℃ Temperature uniformity ≤2℃ Cooling rate 0.7~1℃/min(average) Heating rate 3~5℃/min(average) Humidity range 20%-98...