Paper&Flexible Packaging Testing Instruments

-

YYP103C Full Automatic Colorimeter

Product introduction:

YYP103C Automatic chroma meter is a new instrument developed by our company in the industry’s first fully automatic key

determinationof all colors and brightness parameters, widely used in papermaking, printing, textile printing and dyeing,

chemical industry, building materials, ceramic enamel, grain, salt and other industries, for the determination of the object’s

whiteness and yellowness, color and color difference, can also be measured paper opacity, transparency, light scattering

coefficient, absorption coefficient and ink absorption value.

Product Features:

(1)5 inch TFT color LCD touch screen, the operation is more humanized, new users can be mastered in a short period of time using

the method

(2) Simulation of D65 lighting lighting, using CIE1964 complementary color system and CIE1976 (L*a*b*) color space color

difference formula.

(3) The motherboard brand new design, using the latest technology, CPU uses 32 bits ARM processor,improve the processing

speed, the calculated data is more accurate and rapid electromechanical integration design, abandon cumbersome testing process of the artificial hand wheel is rotated, the real implementation of the test program, a determination of the accurate and efficient.

(4) Using d/o lighting and observation geometry, diffuse ball diameter 150mm, diameter of the testing hole is 25mm

(5) A light absorber, eliminate the effect of specular reflection

(6)Add printer and imported thermal printer, without the use of ink and color, no noise when working, fast printing speed

(7) Reference sample can be physical, but also for data,? Can store up to ten only memory reference information

(8) Has the memory function, even if the long-term shutdown loss of power, memory zeroing, calibration, standard sample and a

reference sample values of the useful information is not lost .

(9) Equipped with a standard RS232 interface, can communicate with computer software

-

YY-CS300 Gloss Meter

Applications:

Gloss meters are mainly used in the surface gloss measurement for paint, plastic, metal, ceramics, building materials and so on. Our gloss meter conform to the DIN 67530, ISO 2813, ASTM D 523, JIS Z8741, BS 3900 Part D5, JJG696 standards and so on.

Product Advantage

1). High Precision

Our gloss meter adopts sensor from Japan, and processor chip from the US to ensure highly precise of the measured data.

Our gloss meters conform to JJG 696 standard for first class gloss meters. Every machine has metrology accreditation certificate from State Key Laboratory of modern metrology and testing instruments and Engineering center of the Ministry of Education in China.

2).Super Stability

Every gloss meter made by us has done the following test:

412 calibration tests;

43200 stability tests;

110 hours of accelerated aging test;

17000 vibration test

3). Comfortable Grab Feeling

The shell is made by Dow Corning TiSLV material, a desirable elastic material. It is resistant to UV and bacteria and do not cause allergy. This design is for better user experience

4).Large Battery Capacity

We fully utilized every space of the device and specially custom made advanced high density lithium battery in 3000mAH , which ensures continuous testing for 54300 times.

5).More Product Pictures

-

YYP122-110 Haze Meter

Instrument Advantages

1). It conforms to both ASTM and ISO international standards ASTM D 1003,ISO 13468,ISO 14782, JIS K 7361 and JIS K 7136.

2). Instrument is with a calibration certification from a third party laboratory.

3). No need to do warm-up, after instrument is calibrated, it can be used. And measurement time is only 1.5 seconds.

4). Three kinds of illuminants A,C and D65 for haze and total transmittance measurement.

5). 21mm test aperture.

6). Open measurement area, no limit on sample size.

7). It can realize both horizontal and vertical measurement to measure different kinds of materials such as sheets, film, liquid, etc.

8). It adopts LED light source whose lifetime can reach 10 years.

-

YYP122-09 Haze Meter

Instrument Advantages

1). It conforms to international standards GB/T 2410, ASTM D1003/D1044 and with a calibration certification from a third party laboratory.

2). No need to do warm-up, after instrument is calibrated, it can be used. And measurement time is only 1.5 seconds.

3). Two kinds of illuminants A,C for haze and total transmittance measurement.

4). 21mm test aperture.

5). Open measurement area, no limit on sample size.

6). It can realize both horizontal and vertical measurement to measure different kinds of materials such as sheets, film, liquid, etc.

7). It adopts LED light source whose lifetime can reach 10 years.

Haze Meter Application:

-

(China)YYP103B Brightness &Color Meter

Brightness Color Meter is widely applied in papermaking, fabric, printing, plastic, ceramic and

porcelain enamel, construction material, grain, salt making and other testing department that

need to test whiteness yellowness, color and chromatism.

-

-

(China)YY-DS200 Series Colorimeter

Product features

(1)Over 30 Measurement Indicators

(2)Evaluate whether the color is jumping light, and provide nearly 40 evaluation light sources

(3)Contains SCI measurement mode

(4)Contains UV for fluorescent color measurement

-

-

-

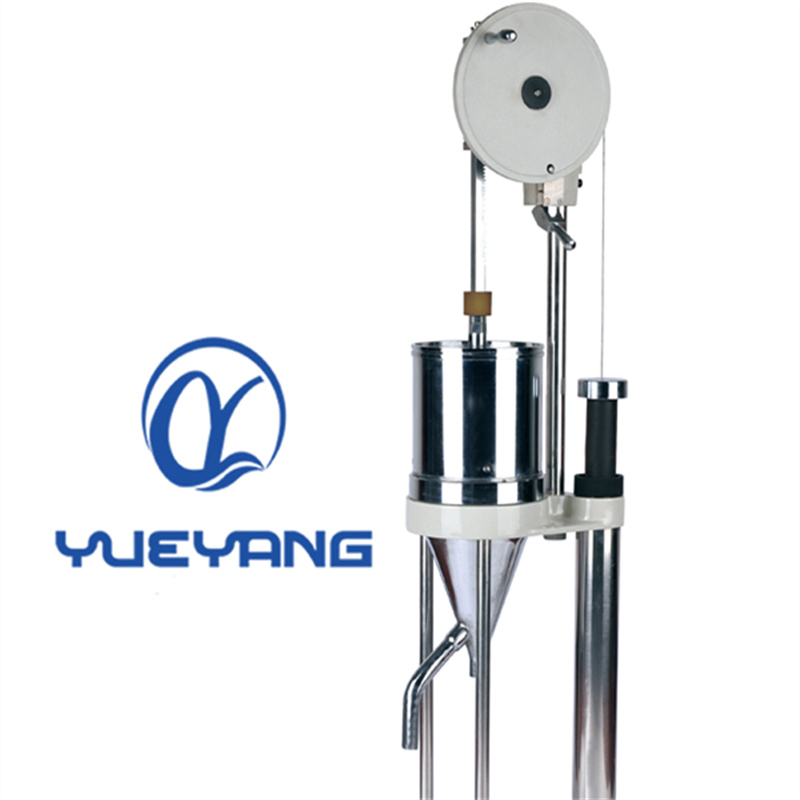

YYP116 Beating Freeness Tester(China)

Product Introduction:

YYP116 Beating Pulp Tester is applied to test the filter ability of suspending pulp liquid. That is to say the determination of the beating degree.

Product features :

According the inverse proportion relation between beating degree and draining velocity of suspending pulp liquid, designed as Schopper-Riegler beating degree tester. YYP116 Beating Pulp

Tester is applied to test filterability of suspending pulp liquid and

research fiber condition and evaluate beating degree.

Product application:

Applying in testing filter ability of suspending pulp liquid, that is to say the determination of the beating degree.

Technical standards:

ISO 5267.1 <Pulps – Determination of drain ability — Part 1: Schopper-Riegler method>

GB/T 3332 <Pulps – Determination of beating degree (Schopper-Riegler method)>

QB/T 1054 <Pulps – Tester of beating degree>

-

YY8503 Crush Tester -Touch-screen type(China)

Product Introduction:

YY8503 Touch screen crush tester also known as computer measurement and control compression tester, cardboard compression tester, electronic compression tester, edge pressure meter, ring pressure meter, is the basic instrument for cardboard/paper compressive strength testing (that is, paper packaging testing instrument), equipped with a variety of fixture accessories can test the ring compression strength of base paper, flat compression strength of cardboard, edge pressure strength, bonding strength and other tests. In order to paper production enterprises to control production costs and improve product quality. Its performance parameters and technical indicators meet the relevant national standards.

Meeting the standard:

1.GB/T 2679.8-1995 —”Determination of ring compression strength of paper and paperboard”;

2.GB/T 6546-1998 “—-Determination of edge pressure strength of Corrugated cardboard”;

3.GB/T 6548-1998 “—-Determination of the bonding strength of Corrugated cardboard”;

4.GB/T 2679.6-1996 “—Determination of flat compression strength of Corrugated base paper”;

5.GB/T 22874 “—Determination of flat compression strength of Single-sided and single-corrugated cardboard”

The following tests can be carried out with the corresponding accessories:

1. Equipped with ring pressure test center plate and special ring pressure sampler to carry out ring pressure strength test (RCT) of cardboard;

2. Equipped with edge press (bonding) sample sampler and auxiliary guide block to carry out corrugated cardboard edge press strength test (ECT);

3. Equipped with peeling strength test frame, corrugated cardboard bonding (peeling) strength test (PAT);

4. Equipped with flat pressure sample sampler to carry out flat pressure strength test (FCT) of corrugated cardboard;

5. Base paper laboratory compressive strength (CCT) and compressive strength (CMT) after corrugating.

-

YY- SCT500 Short Span Compression Tester(China)

- Summary:

The short span compression tester is used for the manufacture of paper and board for cartons and cartons, and is also suitable for paper sheets prepared by the laboratory during pulp testing.

II.Product characteristics:

1. Double cylinder, pneumatic clamping sample, reliable guarantee standard parameters.

2.24-bit precision analog-to-digital converter, ARM processor, fast and accurate sampling

3. 5000 batches of data can be stored for easy access to historical measurement data.

4. Stepper motor drive, accurate and stable speed, and fast return, improve test efficiency.

5. Vertical and horizontal tests can be carried out under the same batch, and vertical and

horizontal average values can be printed.

6. Data saving function of sudden power failure, data retention before power failure after power-on

and can continue testing.

7. Real-time force-displacement curve is displayed during the test, which is convenient for

users to observe the test process.

III. Meeting Standard:

ISO 9895、GB/T 2679·10

-

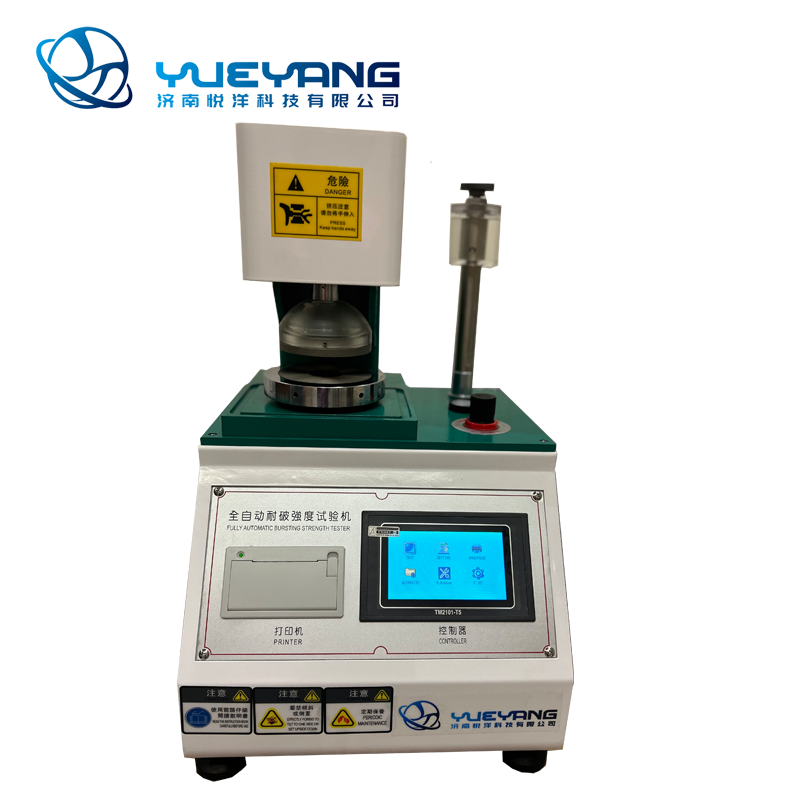

(China)YY109 Automatic Bursting Strength Tester

Meeting Standard:

ISO 2759 Cardboard- -Determination of Breaking Resistance

GB / T 1539 Determination of Board board Resistance

QB / T 1057 Determination of Paper and Board Breaking Resistance

GB / T 6545 Determination of Corrugated Break Resistance Strength

GB / T 454 Determination of Paper Breaking Resistance

ISO 2758 Paper- -Determination of Break Resistance

-

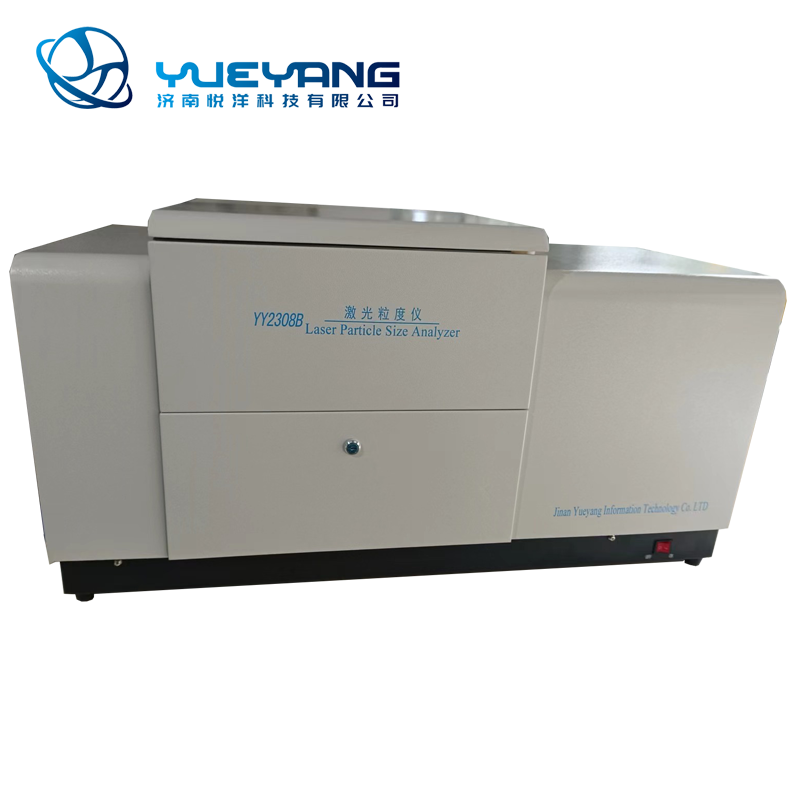

(China) YY2308B Wet &Dry Laser Particle Size Analyzer

YY2308B intelligent full automatic wet&dry laser particle size analyzer adopt laser diffraction theory(Mie and Fraunhofer diffraction), measure size is from 0.01μm to 1200μm(dry 0.1μm-1200μm), Which offer reliable and repeatable particle size analysis for a diverse range of applications.It use dual-beam& multiple spectral detection systems and side light scatter test technology to significantly improve precision and performance of test, It’s the prior choice for industrial production quality control departments and research institutions.

https://www.jnyytech.com/news/yy2308b-dry-wet-laser-particle-size-analyzer-shipments/

-

(China)YYP-5024 Vibration Testing Machine

Application field:

This machine is suitable for toys, electronics, furniture, gifts, ceramics, packaging and other

products for simulated transportation test, in line with the United States and Europe.

Meet the standard:

EN ANSI, UL, ASTM, ISTA International Transportation standards

Equipment technical parameters and characteristics:

1. Digital instrument displays vibration frequency

2. Synchronous quiet belt drive, very low noise

3. The sample clamp adopts guide rail type, easy to operate and safe

4. The base of the machine adopts heavy channel steel with vibration damping rubber pad,

which is easy to install and smooth to run without installing anchor screws

5. Dc motor speed regulation, smooth operation, strong load capacity

6. Rotary vibration (commonly known as horse type), in line with European and American

transportation standards

7. Vibration mode: rotary (running horse)

8. Vibration frequency :100~300rpm

9. Maximum load: 100kg

10. Amplitude: 25.4mm(1 “)

11. Effective working surface size :1200x1000mm

12. Motor power :1HP (0.75kw)

13. Overall size :1200×1000×650 (mm)

14. Timer: 0~99H99m

15. Machine weight :100kg

16. Display frequency accuracy: 1rpm

17. Power supply: AC220V 10A

-

(China)YYP124A Double Wings Package Drop Test Machine

Applications:

The dual-arm drop testing machine is mainly used to assess the impact of the drop shock on the packaging in the actual transportation and loading and unloading process, and to assess the

impact strength of the packaging during the handling process and the rationality of the packaging

design.

Meet the standard;

The double-arm drop test machine conforms to national standards such as GB4757.5-84

JISZ0202-87 ISO2248-1972(E)

-

YYP124B Zero Drop Tester(China)

Applications:

The zero drop tester is mainly used to assess the impact of the drop shock on the packaging in the actual transportation and loading and unloading process, and to assess the impact strength of the packaging in the handling process and the rationality of the packaging design. Zero drop testing machine is mainly used for larger packaging drop test. The machine uses an “E” shaped fork that can move down quickly as the specimen carrier, and the test product is balanced according to the test requirements (surface, edge, Angle test). During the test, the bracket arm moves down at high speed, and the test product falls to the base plate with the “E” fork, and is embedded in the bottom plate under the action of the high efficiency shock absorber. Theoretically, the zero drop testing machine can be dropped from the zero height range, the drop height is set by the LCD controller, and the drop test is automatically performed according to the set height.

Control principle:The design of free falling body, edge, Angle and surface is completed by using microcomputer imported electrical rational design.

Meeting the standard:

GB/T1019-2008

-

YYP124C Single Arm Drop Tester(China)

Instruments use:

Single-arm drop tester This machine is specially used to test the damage of product packaging by falling, and to evaluate the impact strength during transportation and handling process.

Meeting the standard:

ISO2248 JISZ0202-87 GB/T4857.5-92

Instruments features:

Single-arm drop testing machine can be free drop test on the surface, Angle and edge of the

package, equipped with digital height display instrument and the use of decoder for height tracking,

so that the product drop height can be accurately given, and the preset drop height error is not more than 2% or 10MM. The machine adopts single-arm double-column structure, with electric reset, electronic control drop and electric lifting device, easy to use; The unique buffer device greatly

improves the service life, stability and safety of the machine. Single arm setting for easy placement

of products.

-

(China)YY-WT0200–Electronic balance

[Scope of application] :

It is used for testing gram weight, yarn count, percentage, particle number of textile, chemical, paper and other industries.

[Related standards] :

GB/T4743 “yarn linear density determination Hank method”

ISO2060.2 “Textiles – Determination of yarn linear density – Skein method”

ASTM, JB5374, GB/T4669/4802.1, ISO23801, etc

[Instrument characteristics] :

1. Using high precision digital sensor and single chip microcomputer program control;

2. With tare removal, self-calibration, memory, counting, fault display and other functions;

3. Equipped with special wind cover and calibration weight;

[Technical parameters] :

1. Maximum weight :200g

2. Minimum degree value :10mg

3. Verification value :100mg

4. Accuracy level: III

5. Power supply :AC220V±10% 50Hz 3W

-

(China)YYP-R2 Oil Bath Heat Shrink Tester

Instrument Introduction:

The heat shrink tester is suitable for testing the heat shrink performance of materials, which can be used for plastic film substrate (PVC film, POF film, PE film, PET film, OPS film and other heat shrink films), flexible packaging composite film, PVC polyvinyl chloride hard sheet, solar cell backplane and other materials with heat shrink performance.

Instrument characteristics:

1. Microcomputer control, PVC menu type operation interface

2. Humanized design, easy and fast operation

3. High-precision circuit processing technology, accurate and reliable test

4. Liquid non-volatile medium heating, heating range is wide

5. Digital P.I.D temperature control monitoring technology can not only quickly reach the set temperature, but also effectively avoid temperature fluctuations

6. Automatic timing function to ensure test accuracy

7. Equipped with standard sample holding film grid to ensure that the sample is stable without interference from temperature

8. Compact structure design, light and easy to carry