l Product Features:

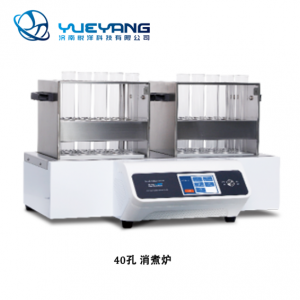

1) This digestion system is designed with a curve heating digestion furnace as the main body, combined with exhaust gas collection and exhaust gas neutralization. It realizes the one-click completion of the sample processing process from ① sample digestion → ② exhaust gas collection → ③ exhaust gas neutralization treatment → ④ stop heating when digestion is completed → ⑤ separate the digestion tube from the heating body and cool down for standby. It achieves the automation of the sample digestion process, improves the working environment, and reduces the workload of the operators.

2) Test tube rack in-place detection: If the test tube rack is not placed or not placed properly, the system will alarm and not work, preventing equipment damage caused by running without samples or incorrect placement of test tubes.

3) Anti-pollution tray and alarm system: The anti-pollution tray can prevent acid liquid from the exhaust gas collection port from polluting the operation table or other environments. If the tray is not removed and the system is run, it will alarm and stop running.

4) The digestion furnace is a sample digestion and conversion equipment developed based on the classic wet digestion principle. It is mainly used in agriculture, forestry, environmental protection, geology, petroleum, chemical, food and other departments, as well as universities and research institutions for the digestion treatment of plant, seed, feed, soil, ore and other samples before chemical analysis. It is the best matching product for Kjeldahl nitrogen analyzers.

5) The S graphite heating module has good uniformity and small temperature buffering, with a designed temperature up to 550℃.

6) The L aluminum alloy heating module has fast heating, long service life, and wide application. The designed temperature is 450℃.

7) The temperature control system adopts a 5.6-inch color touch screen with Chinese-English conversion, and is simple to operate.

8) The formula program input adopts a table-based rapid input method, which is logical, fast, and less prone to errors.

9) 0-40 segments of programs can be freely selected and set.

10) Single-point heating and curve heating dual modes can be freely selected.

11) Intelligent P, I, D self-tuning ensures high, reliable and stable temperature control accuracy.

12) Segmented power supply and anti-power-off restart function can prevent potential risks from occurring.

13) Equipped with over-temperature, over-pressure and over-current protection modules.