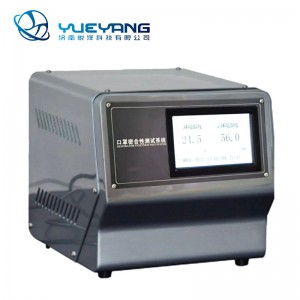

YYP-400DT Rapid loading Melft Flow Indexer

III. Model&Configuration:

|

Model |

Configuration |

| YYP-400DT | Touch screen;Thermal printer;

Fast loading ; Handwheel; MFR&MVR Testing Method |

IV.Technical Parameters:

1. Temperature range: 0-400℃, fluctuation range: ±0.2℃;

2. Temperature gradient: ≤0.5℃ (the upper end of the mold inside the barrel 10 ~ 70mm in the tropical area);

3. Temperature display resolution: 0.01℃;

4. Barrel length: 160 mm; Inner diameter: 9.55±0.007mm;

5. Die length: 8± 0.025mm; Inner diameter: 2.095mm;

6. Cylinder temperature recovery time after feeding: ≤4min;

7.Measuring range: 0.01-600.00g /10min(MFR); 0.01-600.00 cm3/10min(MVR); 0.001-9.999 g/cm3 (melt density);

8. Displacement measurement range: 0-30mm, accuracy: ±0.02mm;

9. The weight meets the range: 325g-21600g discontinuous, the combined load can meet the standard requirements;

10. Weight load accuracy: ≤±0.5%;

11. Power supply: AC220V 50Hz 550W;

12. Dimensions: Touch screen: 580×480×530 (L* W*H)

13. Weight: about 110kg.