Products

-

(China)YYP108-10A Film Tearing Tester

Design criteria:

1.ISO 6383-1 plastics. Determination of tear resistance of films and sheets. Part 1: Split pants type tearing method

2.ISO 6383-2 plastics. Films and sheets – Determination of tear resistance. Part 2: Elmando Method

3.ASTM D1922 Standard test Method for Determination of Resistance to Expansion Tearing of plastic films and sheets by the pendulum Method

4.GB/T 16578-1 Plastic films and sheets – Determination of tear resistance – Part 1: trouser tear method

5.ISO 6383-1-1983, ISO 6383-2-1983, ISO 1974, GB/T16578.2-2009, GB/T 455, ASTM D1922, ASTM D1424, ASTM D689, TAPPI T414

Product Features:

1. The system is controlled by computer and adopts automatic and electronic measurement method, which is convenient for users to carry out test operation quickly and conveniently

2. Pneumatic sample clamping and pendulum release effectively avoid systematic errors caused by human factors

3. The computer level adjustment auxiliary system can ensure that the instrument is always in the best test state

4. Equipped with multiple groups of pendulum capacity to meet different test needs of users

5. Professional software supports data output of various test units

6. Standard RS232 interface to facilitate external access and data transmission of the system

-

(China)YY-PNY-10 Torque tester-10 Nm

Instruments Introductions:

YY-CRT-01 Verticality Deviation (circular runout) Tester is suitable for ampoules, mineral water

bottles, beer bottles and other round bottle packaging round run-out test. This product conforms

to national standards, simple structure, wide range of application, convenient and durable,

high precision. It is an ideal testing instrument for pharmaceutical, pharmaceutical packaging,

food, daily chemical and other enterprises and drug inspection institutions.

Meet the standard:

QB 2357-1998、YBB00332004、YBB00352003、YBB00322003、YBB00192003、

YBB00332002、YBB00052005、YBB00042005、QB/T1868

-

(China)YY-CRT-01 Verticality Deviation (circular runout) Tester

Instruments Introductions:

YY-CRT-01 Verticality Deviation (circular runout) Tester is suitable for ampoules, mineral water

bottles, beer bottles and other round bottle packaging round run-out test. This product conforms

to national standards, simple structure, wide range of application, convenient and durable,

high precision. It is an ideal testing instrument for pharmaceutical, pharmaceutical packaging,

food, daily chemical and other enterprises and drug inspection institutions.

Meet the standard:

QB 2357-1998、YBB00332004、YBB00352003、YBB00322003、YBB00192003、

YBB00332002、YBB00052005、YBB00042005、QB/T1868

-

(China)YY832 Multifunctional Sock Stretching Tester

Applicable standards:

FZ/T 70006, FZ/T 73001, FZ/T 73011, FZ/T 73013, FZ/T 73029, FZ/T 73030, FZ/T 73037, FZ/T 73041, FZ/T 73048 and other standards.

Product features:

1.Large screen color touch screen display and control, Chinese and English interface menu-type operation.

2. Delete any measured data and export the test results to EXCEL documents for easy connection

with the user’s enterprise management software.

3.Safety protection measures: limit, overload, negative force value, overcurrent, overvoltage protection, etc.

4. Force value calibration: digital code calibration (authorization code).

5. (host, computer) two-way control technology, so that the test is convenient and fast, the test results are rich and diverse (data reports, curves, graphs, reports).

6. Standard modular design, convenient instrument maintenance and upgrade.

7. Support online function, test report and curve can be printed out.

8. One total of four sets of fixtures, all installed on the host, can complete the socks straight extension and horizontal extension of the test.

9. The length of the measured tensile specimen is up to three meters.

10. With socks drawing special fixture, no damage to the sample, anti-slip, the stretching process of the clamp sample does not produce any form of deformation.

-

(China)YY611B02 Color Fastness Xenon Chamber

Meet the standard:

AATCC16, 169, ISO105-B02, ISO105-B04, ISO105-B06, ISO4892-2-A, ISO4892-2-B, GB/T8427, GB/T8430, GB/T14576, GB/T16422.2, 1865, 1189, GB/T15102 , GB/T15104, JIS 0843, GMW 3414, SAEJ1960, 1885, JASOM346, PV1303, ASTM G155-1, 155-6, GB/T17657-2013, etc.

Product features:

1. Meet AATCC, ISO, GB/T, FZ/T, BS a number of national standards.

2.Color touch screen display, a variety of expressions: numbers, charts, etc.; It can display real-time monitoring curves of light irradiance, temperature and humidity. And store a variety of detection standards, convenient for users to directly select and call.

3.Safety protection monitoring points (irradiance, water level, cooling air, bin temperature, bin door, overcurrent, overpressure) to achieve unmanned operation of the instrument.

4.Imported long arc xenon lamp lighting system, true simulation of daylight spectrum.

5.The irradiance sensor position is fixed, eliminating the measurement error caused by the rotating vibration of the turntable and the refraction of the light caused by the sample turntable turning to different positions.

6. Light energy automatic compensation function.

7.Temperature (irradiation temperature, heater heating,), humidity (multiple groups of ultrasonic atomizer humidification, saturated water vapor humidification,) dynamic balance technology.

8. Accurate and fast control of BST and BPT.

9. Water circulation and water purification device.

10.Each sample independent timing function.

11.Double circuit electronic redundancy design to ensure that the instrument for a long time continuous trouble-free operation.

-

(China)YY-12G Colour Fastness Whashing

Meet the standard:

GB/T12490-2007, GB/T3921-2008 “Textile color fastness test Color fastness to soap washing”

ISO105C01 / our fleet / 03/04/05 C06/08 / C10 “family and commercial washing fastness”

JIS L0860/0844 “Test method for color fastness to Dry cleaning”

GB5711, BS1006, AATCC61/1A/2A/3A/4A/5A and other standards.

Instrument characteristics:

1. 7 inch color touch screen display and operation, Chinese and English bilingual operation interface.

2. 32-bit multi-function motherboard processing data, accurate control, stable, running time, test temperature can be set by itself.

3. The panel is made of special steel, laser engraving, handwriting is clear, not easy to wear;

4.Metal keys, sensitive operation, not easy to damage;

5. Precision reducer, synchronous belt transmission, stable transmission, low noise;

6.Solid state relay control heating tube, no mechanical contact, stable temperature, no noise, long life;

7. Equipped with anti-dry fire protection water level sensor, instant detection of water level, high sensitivity, safe and reliable;

8.Using PID temperature control function, effectively solve the temperature “overshoot” phenomenon;

9.The machine box and rotating frame are made of high-quality 304 stainless steel, durable, easy to clean;

10.The studio and the preheating room are independently controlled, which can preheat the sample while working, greatly shortening the test time;

11.With high quality foot, easy to move;

-

(China)YY571D AATCC Electric Crock Meter

Instrument use:

Used in textile, hosiery, leather, electrochemical metal plate, printing and other industries to evaluate

the color fastness friction test.

Meet the standard:

GB/T5712, GB/T3920, ISO105-X12 and other commonly used test standards, can be dry, wet friction

test function.

-

(China)YYP111B Folding Resistance Tester

Overview:

MIT folding resistance is a new type of instrument developed by our company according to the

national standard GB/T 2679.5-1995 (determination of folding resistance of paper and paperboard).

The instrument has the parameters included in the standard test, conversion, adjustment, display,

memory, printing, with data processing function, can directly obtain the statistical results of the data.

The instrument has the advantages of compact structure, small size, light weight, full function,

bench position, easy operation and stable performance, and is suitable for the determination of

bending resistance of various paperboards.

-

(China)YYP 501B Automatic Smoothness Tester

YYP501B Automatic smoothness tester is a special instrument for determining the smoothness of paper. According to the international general Buick (Bekk) type smoother working principle design. In mechanical design, the instrument eliminates the manual pressure structure of the traditional lever weight hammer, innovatively adopts CAM and spring, and uses synchronous motor to automatically rotate and load the standard pressure. Greatly reduce the volume and weight of the instrument. The instrument uses a 7.0 inch large color touch LCD screen display, with Chinese and English menus. The interface is beautiful and friendly, the operation is simple, and the test is operated by one key. The instrument has added an “automatic” test, which can greatly save time when testing high smoothness. The instrument also has the function of measuring and calculating the difference between two sides. The instrument adopts a series of advanced components such as high-precision sensors and original imported oil-free vacuum pumps. The instrument has various parameter testing, conversion, adjustment, display, memory and printing functions included in the standard, and the instrument has powerful data processing capabilities, which can directly obtain the statistical results of the data. This data is stored on the main chip and can be viewed with a touch screen. The instrument has the advantages of advanced technology, complete functions, reliable performance and easy operation, and is an ideal test equipment for papermaking, packaging, scientific research and product quality supervision and inspection industries and departments.

-

(China)YYPL6-D Automatic Handsheet Former

Summary

YYPL6-D automatic handsheet former is a kind of laboratory equipment for making and forming

paper pulp by hand and carrying out rapid vacuum drying. In the laboratory, plants, minerals and

other fibers after cooking, beating, screening, the pulp is standard dredging, and then put into the

sheet cylinder, stirring after rapid extraction molding, and then pressed on the machine, vacuum

drying, forming a diameter of 200mm circular paper, the paper can be used as a further physical detection of paper samples.

This machine is a set of vacuum extraction forming, pressing, vacuum drying in one of the full

electric control of the forming part can be automatic intelligent control and manual control of two

ways, wet paper drying by instrument control and remote intelligent control, the machine is suitable

for all kinds of microfiber, nanofiber, super thick paper page extraction forming and vacuum drying.

The operation of the machine adopts two ways of electric and automatic, and the user formula is provided in the automatic file, the user can store different sheet sheet parameters and drying

heating parameters according to different experiments and stock, all parameters are controlled

by the programmable controller, and the machine allows electric control to control sheet sheet

program and instrument control heating. The equipment has three stainless steel drying bodies,

graphic dynamic display of sheet process and drying temperature time and other parameters. The control system adopts Siemens S7 series PLC as the controller, monitors each data with TP700

panel in the Jingchi series HMI, completes the formula function on the HMI, and controls and

monitors each control point with buttons and indicators.

-

(China)YYPL8-A laboratory Standard Pattern Press

Summary:

Laboratory standard pattern press is an automatic paper pattern press designed and produced

according to ISO 5269/1-TAPPI, T205-SCAN, C26-PAPTAC C4 and other paper standards. It is a

press used by the paper making laboratory to improve the density and smoothness of the pressed

sample, reduce the moisture of the sample, and improve the strength of the object. According to the standard requirements, the machine is equipped with automatic timing pressing, manual timing

pressing and other functions, and the pressing force can be accurately adjusted.

-

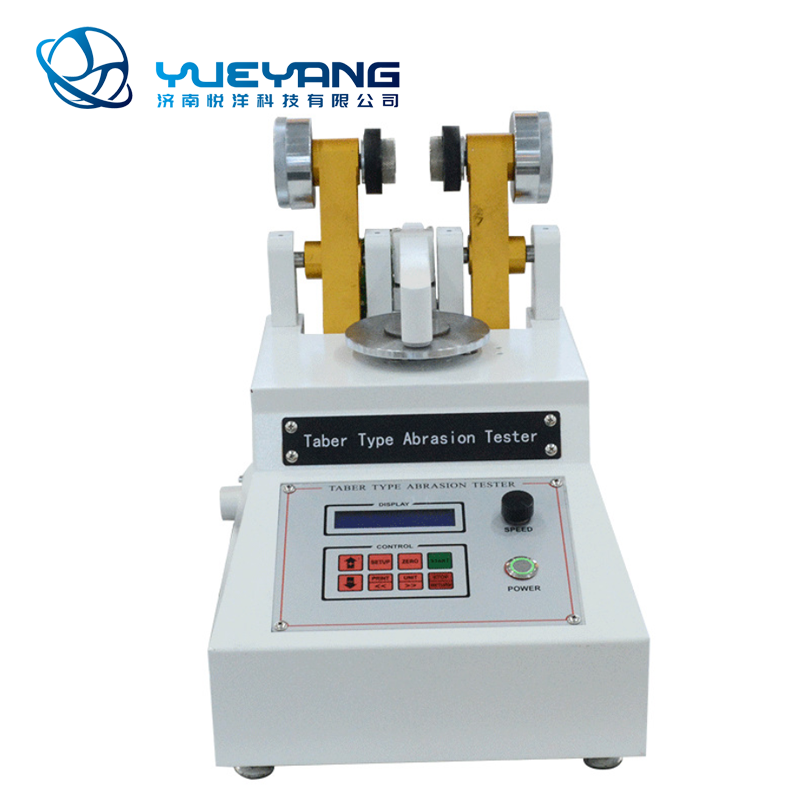

(China)YY-TABER Leather Abrasion Tester

Instruments Introduction:

This machine is suitable for cloth, paper, paint, plywood, leather, floor tile, floor, glass, metal film,

natural plastic and so on. The test method is that the rotating test material is supported by a

pair of wear wheels, and the load is specified. The wear wheel is driven when the test

material is rotating, so as to wear the test material. The wear loss weight is the weight

difference between the test material and the test material before and after the test.

Meeting the standard:

DIN-53754、53799、53109,TAPPI-T476,ASTM-D3884,ISO5470-1,GB/T5478-2008

-

(China)YYPL 200 Leather Tensile Strengh Tester

I.Applications:

Suitable for leather, plastic film, composite film, adhesive, adhesive tape, medical patch, protective

film, release paper, rubber, artificial leather, paper fiber and other products tensile strength, peeling strength, deformation rate, breaking force, peeling force, opening force and other performance tests.

II.Application field:

Tape, automotive, ceramics, composite materials, construction, food and medical equipment, metal,

paper, packaging, rubber, textiles, wood, communication and various special-shaped materials

-

(China)YYP-4 Leather Dynamic Waterproof Tester

I.Product Introduction:

Leather, artificial leather, cloth, etc., under the water on the outside, the bending action is applied

to measure the permeability resistance index of the material. Number of test pieces 1-4 Counters 4 groups, LCD, 0~ 999999,4 sets ** 90W Volume 49×45×45cm Weight 55kg Power 1 #, AC220V,

2 A.

II.Test principle:

Leather, artificial leather, cloth, etc., under the water on the outside, the bending action is applied to measure the permeability resistance index of the material.

-

(China)YYP 50L Constant Temperature&Humidity Chamber

Meeting standard:

The performance indicators meet the requirements of GB5170, 2, 3, 5, 6-95 “Basic parameter Verification method of environmental test equipment for electrical and electronic products Low temperature, high temperature, constant wet heat, alternating wet heat test equipment”

Basic environmental test procedures for electrical and electronic products Test A: Low temperature

test method GB 2423.1-89 (IEC68-2-1)

Basic environmental test procedures for electrical and electronic products Test B: High temperature

test method GB 2423.2-89 (IEC68-2-2)

Basic environmental test procedures for electrical and electronic products Test Ca: Constant wet

heat test method GB/T 2423.3-93 (IEC68-2-3)

Basic environmental test procedures for electrical and electronic products Test Da: Alternating

humidity and heat test method GB/T423.4-93(IEC68-2-30)

-

(China)YYN06 Bally Leather Flexing Tester

I.Applications:

Leather flexure testing machine is used for the flexure test of shoe upper leather and thin leather

(shoe upper leather, handbag leather, bag leather, etc.) and cloth folding back and forth.

II.Test principle

The flexibility of the leather refers to the bending of one end surface of the test piece as the inside

and the other end surface as the outside, especially the two ends of the test piece are installed on

the designed test fixture, one of the fixtures is fixed, the other fixture is reciprocated to bend the

test piece, until the test piece is damaged, record the number of bending, or after a certain number

of bending. Look at the damage.

III.Meet the standard

BS-3144, JIB-K6545, QB1873, QB2288, QB2703, GB16799-2008, QB/T2706-2005 and other

leather flexure inspection method required specifications.

-

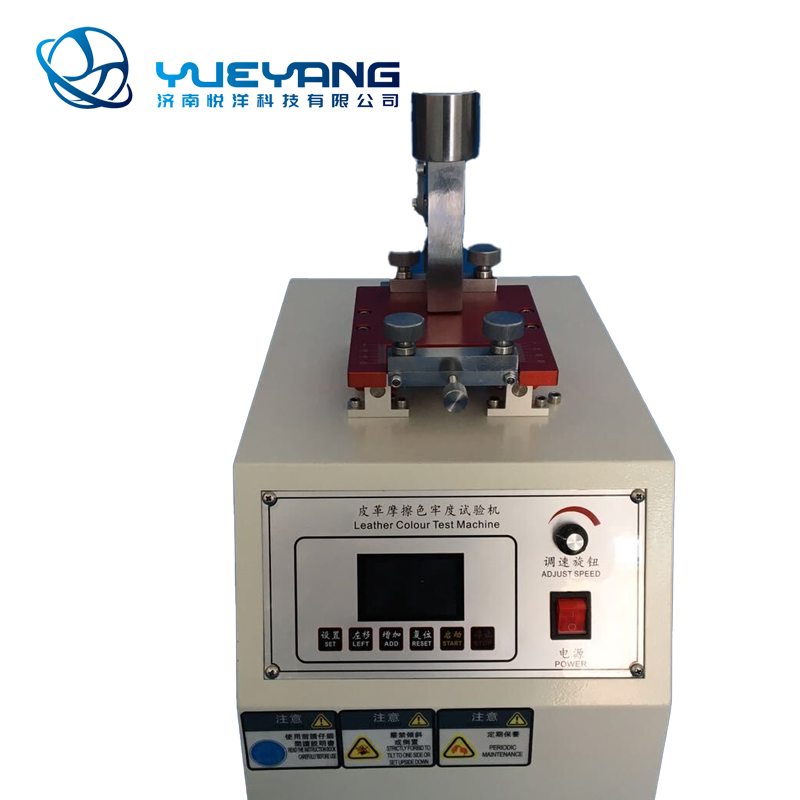

(China)YY127 Leather Color Test Machine

Summary:

Leather color test machine in the test of dyed upper, lining leather, after friction damage and

decolorization degree, can do dry, wet friction two tests, the test method is dry or wet white wool

cloth, wrapped in the surface of the friction hammer, and then the repeated friction clip on the test bench test piece, with power off memory function

Meet the standard:

The machine meet ISO / 105, ASTM/D2054, AATCC / 8, JIS/L0849 ISO – 11640, SATRA PM173, QB/T2537 standard, etc

-

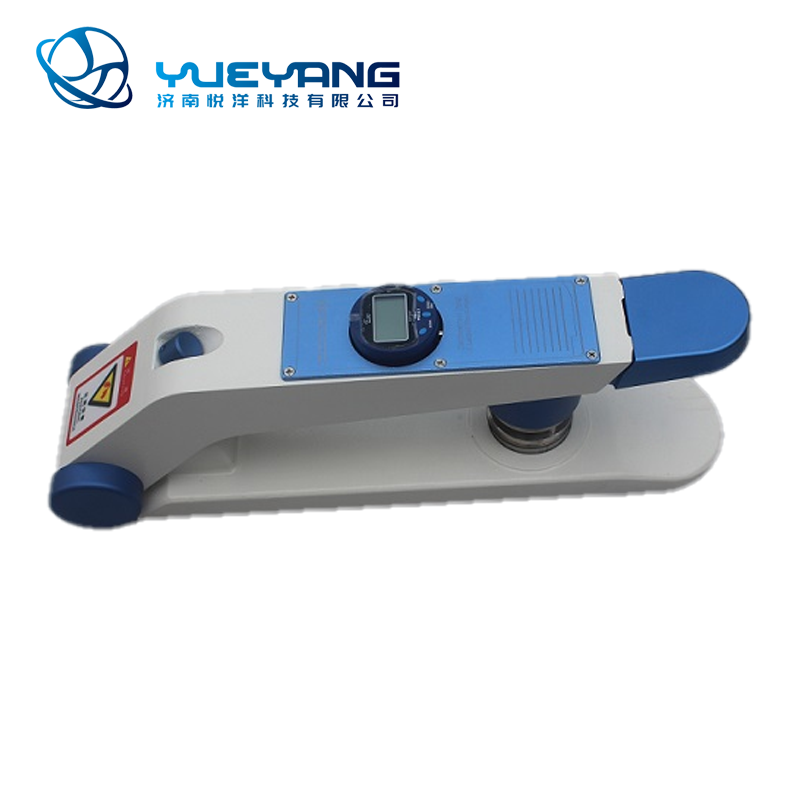

(China)YY119 Leather Softness Tester

I.Equipment features:

This instrument fully conforms to IULTCS,TUP/36 standard, accurate, beautiful, easy to operate

and maintain, portable advantages.

II.Equipment application:

This instrument is specially used to measure the leather, hides, in order to understand the same

batch or the same package of leather in the soft and hard is uniform, can also test a single piece

of leather, each part of the soft difference.

-

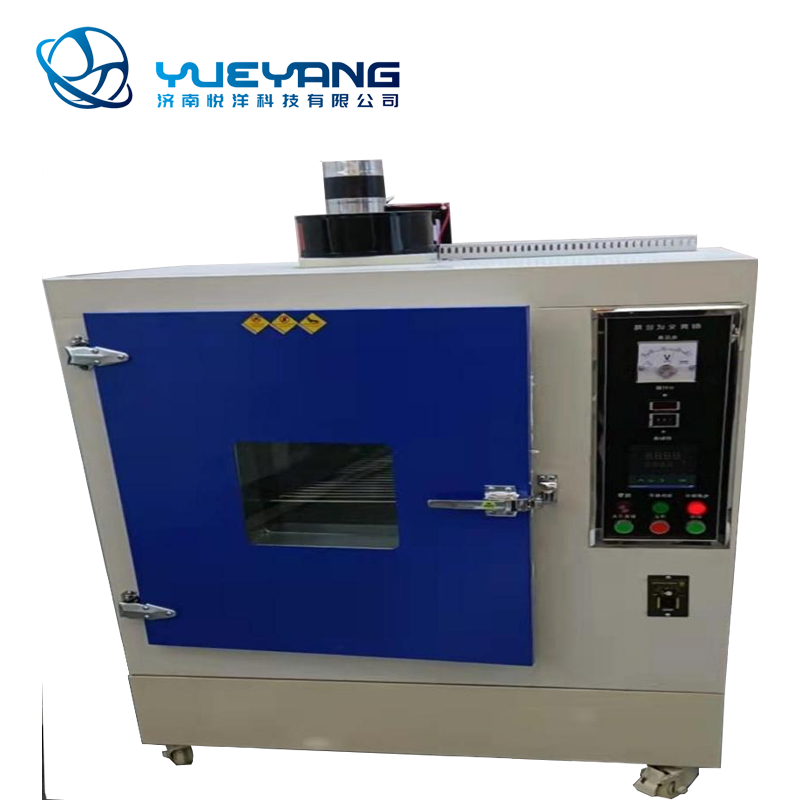

(China)YY NH225 Yellowing Resistance Aging Oven

Summary:

It is manufactured in accordance with ASTM D1148 GB/T2454HG/T 3689-2001, and its function

is to simulate the ultraviolet radiation and heat of sunlight. The sample is exposed to ultraviolet

radiation and temperature in the machine, and after a period of time, the degree of yellowing

resistance of the sample is observed. The staining gray label can be used as a reference to

determine the grade of yellowing. The product is affected by sunlight radiation during use or the

influence of the container environment during transportation, resulting in the color change of the

product.

-

(China)YYP123C Box Compression Tester

Instruments features:

1.After the completion of the test automatic return function, automatically judge the crushing force

and automatically save the test data

2. Three kinds of speed can be set, all Chinese LCD operation interface, a variety of units to

choose from.

3.Can input the relevant data and automatically convert the compressive strength, with

packaging stacking test function; Can directly set the force, time, after the completion of

the test automatically shut down.

4. Three working modes:

Strength test: can measure the maximum pressure resistance of the box;

Fixed value test: the overall performance of the box can be detected according to the set pressure;

Stacking test: According to the requirements of national standards, stacking tests can be carried

out under different conditions such as 12 hours and 24 hours.

III.Meet the standard:

GB/T 4857.4-92 Pressure test method for packaging transportation packages

GB/T 4857.3-92 Test method for static load stacking of packaging and transportation packages.