Rubber&Plastic testing Instruments

-

(China)YY-6009 Akron Abrasion Tester

I.Introductions: The Akron Abrasion Tester is developed according to BS903 and GB/T16809 specifications. The wear resistance of rubber products such as soles, tires and chariot tracks is specially tested. The counter adopts electronic automatic type, can set the number of wear revolutions, reach no fixed number of revolutions and automatic stop. II.Main Functions: The mass loss of rubber disc before and after grinding was measured, and the volume loss of rubber disc was calculated according t... -

(China)YY-6010 DIN Abrasion Tester

I. Introductions: Wear-resistant testing machine will test the test piece fixed in the testing machine seat, through the test seat to test the sole to increase a certain pressure in the rotation of the testing machine covered with wear-resistant sandpaper roller friction forward motion, a certain distance, the measurement of the weight of the test piece before and after friction, According to the specific gravity of the sole test piece and the correction coefficient of standard rubber, the r... -

(China)YY-6016 Vertical Rebound Tester

I. Introductions: The machine is used to test the elasticity of rubber material with a free drop hammer. First adjust the level of the instrument, and then lift the drop hammer to a certain height. When placing the test piece, attention should be paid to making the drop point 14mm away from the edge of the test piece. The average rebound height of the fourth, fifth and sixth tests was recorded, excluding the first three tests. II.Main functions: The machine adopts the standard test method of ... -

(China)YY-6018 Shoe Heat Resistance Tester

I. Introductions: Shoe heat resistance tester used to test the high temperature resistance of sole materials (including rubber, polymer). After contacting the sample with the heat source (metal block at constant temperature) at a fixed pressure for about 60 seconds, observe the surface damage of the specimen, such as softening, melting, cracking, etc., and determine whether the specimen is qualified according to the standard. II.Main functions: This machine adopts vulcanized rubber or thermop... -

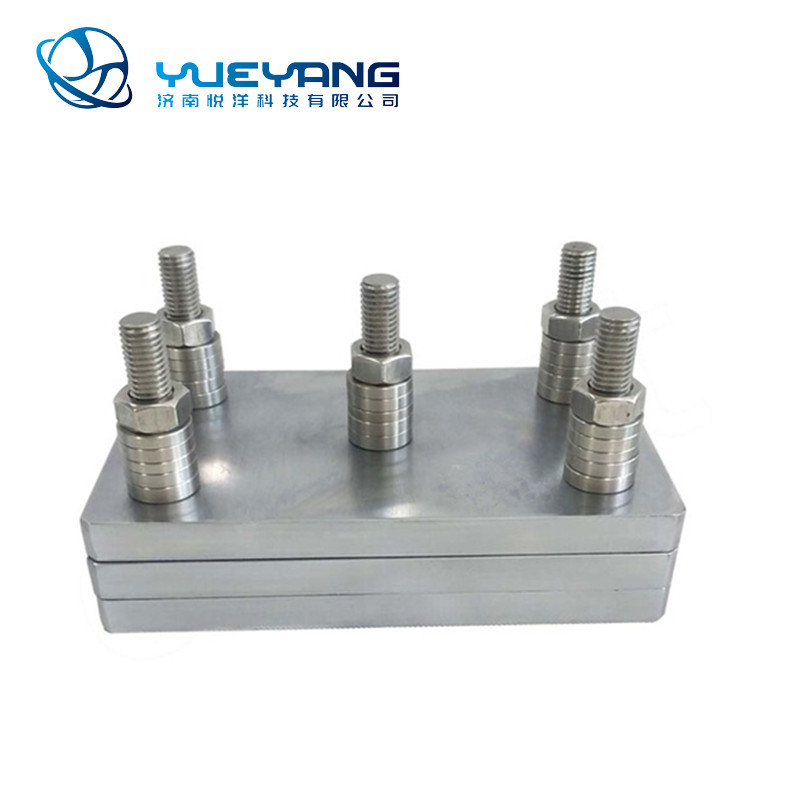

(China)YY-6024 Compression Set Fixture

I. Introductions: This machine is used for rubber static compression test, sandwiched between the plate, with the screw rotation, compression to a certain ratio and then put into a certain temperature oven, after the specified time to take, remove the test piece, cool for 30 minutes, measure its thickness, put into the formula to find its compression skew. II. Meeting standard: GB/T 7759-1996 ASTM-D395 III.Technical Specifications: 1. The matching distance ring: 4 mm/4. 5 mm/5mm/9. 0 mm/9. 5... -

(China)YY-6027-PC Sole Puncture Resistant Tester

I. Introductions: A:(static pressure test) : test the shoe head at a constant rate through the testing machine until the pressure value reaches the specified value, measure the minimum height of the sculpted clay cylinder inside the test shoe head, and evaluate the compression resistance of the safety shoe or protective shoe head with its size. B: (Puncture test) : The testing machine drives the puncture nail to puncture the sole at a certain speed until the sole is completely pierced or reac... -

(China)YY-6077-S Temperature &Humidity Chamber

I. Introductions: High temperature &high humidity, low temperature & low humidity test products, suitable for electronic, electrical appliances, batteries, plastics, food, paper products, vehicles, metal, chemistry, building materials, research institute, inspection and quarantine bureau, universities and other industry units for quality control testing. II. Freezing system: RRefrigeration system: adopting France tecumseh compressors, European and American type high efficiency powe... -

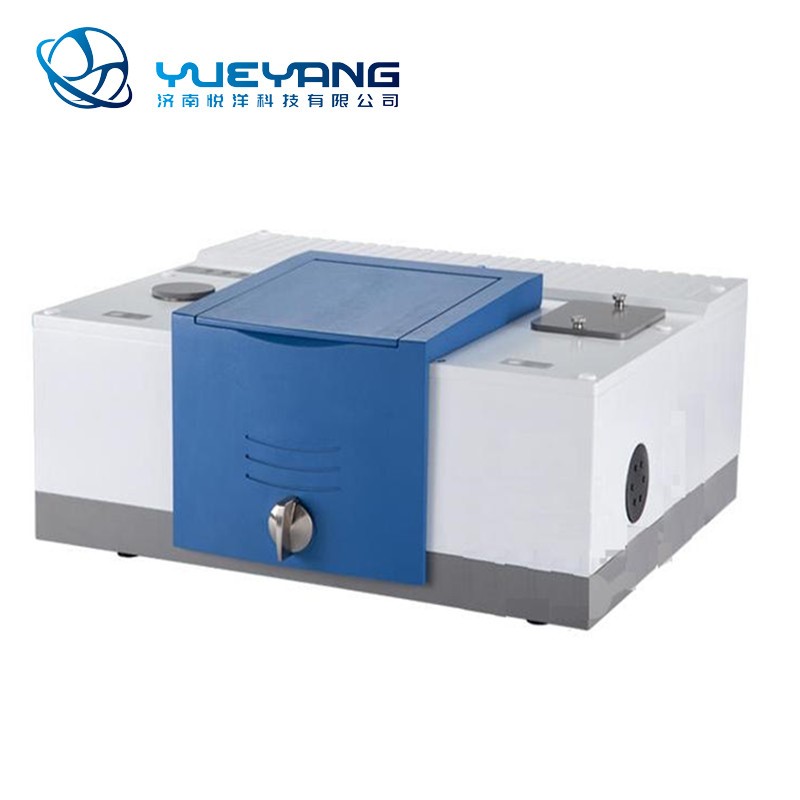

(China)FTIR-2000 Fourier Transfor Infrared Spectrometer

FTIR-2000 Fourier infrared spectrometer can be widely used in pharmaceutical, chemical, food, petrochemical, jewelry, polymer, semiconductor, material science and other industries, the instrument has strong expansion function, can connect a variety of conventional transmission, diffuse reflection, ATR attenuated total reflection, non-contact external reflection and other accessories, The FTIR-2000 will be the perfect choice for your QA/QC application analysis in universities, research institu... -

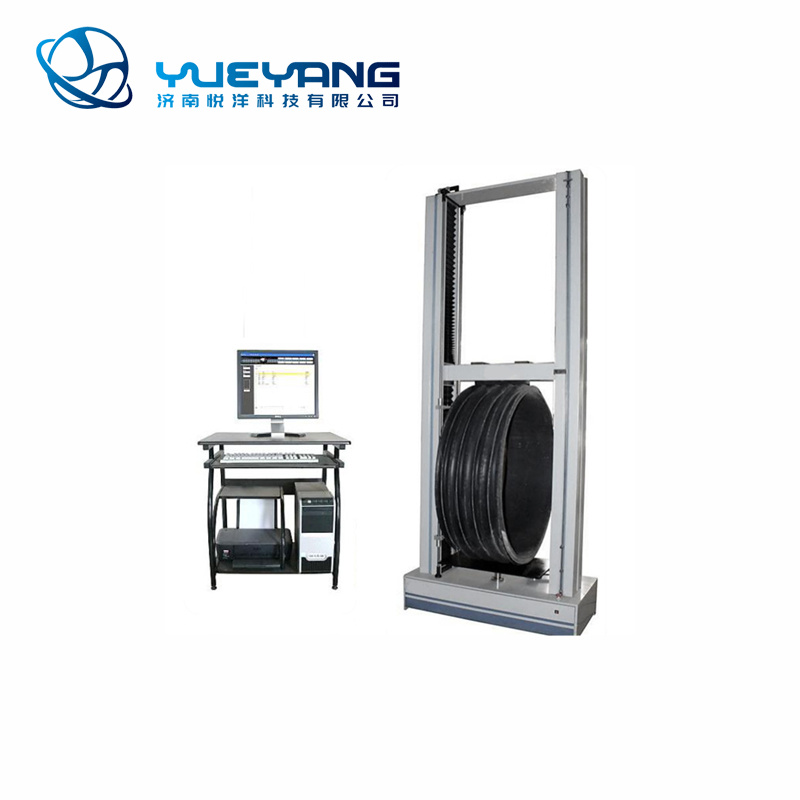

(China)YY101 Single Column Universal Testing Machine

This machine can be used for rubber, plastic, foam material, plastic, film, flexible packaging, pipe, textile, fiber, nano material, polymer material, polymer material, composite material, waterproof material, synthetic material, packaging belt, paper, wire and cable, optical fiber and cable, safety belt, insurance belt, leather belt, footwear, rubber belt, polymer, spring steel, stainless steel, castings, copper pipe, non-ferrous metal, Tensile, compression, bending, tearing, 90° peeling, 18... -

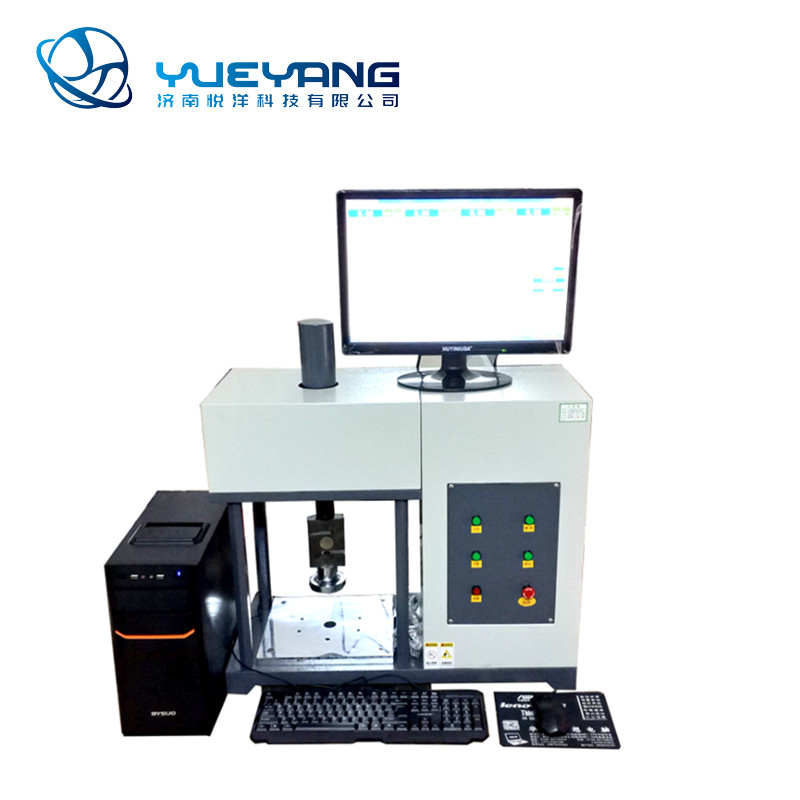

(China)YY0306 Footwear Slip Resistance Tester

Suitable for the anti-skid performance test of whole shoes on glass, floor tile, floor and other materials. GBT 3903.6-2017 “General Test Method for Footwear Anti-slip Performance”, GBT 28287-2012 “Test Method for Foot Protective Shoes Anti-slip Performance”, SATRA TM144, EN ISO13287:2012, etc. 1. The selection of high-precision sensor test more accurate; 2. The instrument can test the friction coefficient and test the research and development of ingredients to make ba... -

(China)YYP-800D Digital Display Shore Hardness Tester

YYP-800D high precision digital display shore/Shore hardness tester (shore D type), it is mainly used for measuring hard rubber, hard plastics and other materials. For example: thermoplastics, hard resins, plastic fan blades, plastic polymer materials, acrylic, Plexiglass, UV glue, fan blades, epoxy resin cured colloids, nylon, ABS, Teflon, composite materials, etc. Comply with ASTM D2240, ISO868, ISO7619, GB/T2411-2008 and other standards. HTS-800D (Pin size) (1) Built-in high precision dig... -

(China)YYP-800A Digital Display Shore Hardness Tester (Shore A)

YYP-800A digital display Shore hardness tester is A high precision rubber hardness tester (Shore A) manufactured by YUEYANG TECHNOLOGY INSTRUNENTS. It is mainly used to measure the hardness of soft materials, such as natural rubber, synthetic rubber, butadiene rubber, silica gel, fluorine rubber, such as rubber seals, tires, cots, cable , and other related chemical products. Comply with GB/T531.1-2008, ISO868, ISO7619, ASTM D2240 and other relevant standards. (1) Maximum locking function, av... -

(China)YY026H-250 Electronic Tensile Strength Tester

This instrument is the domestic textile industry powerful test configuration of high-grade, perfect function, high precision, stable and reliable performance model. Widely used in yarn, fabric, printing and dyeing, fabric, clothing, zipper, leather, nonwoven, geotextile and other industries of breaking, tearing, breaking, peeling, seam, elasticity, creep test.

-

YYP-JM-720A Rapid Moisture Meter

Main Technical Parameters:

Model

JM-720A

Maximum weighing

120g

Weighing precision

0.001g(1mg)

Non-water electrolytic analysis

0.01%

Measured data

Weight before drying, weight after drying, moisture value, solid content

Measuring range

0-100% moisture

Scale size(mm)

Φ90(stainless steel)

Thermoforming Ranges(℃)

40~~200(increasing temperature 1°C)

Drying procedure

Standard heating method

Stop method

Automatic stop, timing stop

Setting time

0~99分 1 Minute interval

Power

600W

Power Supply

220V

Options

Printer /Scales

Packaging Size(L*W*H)(mm)

510*380*480

Net Weight

4kg

-

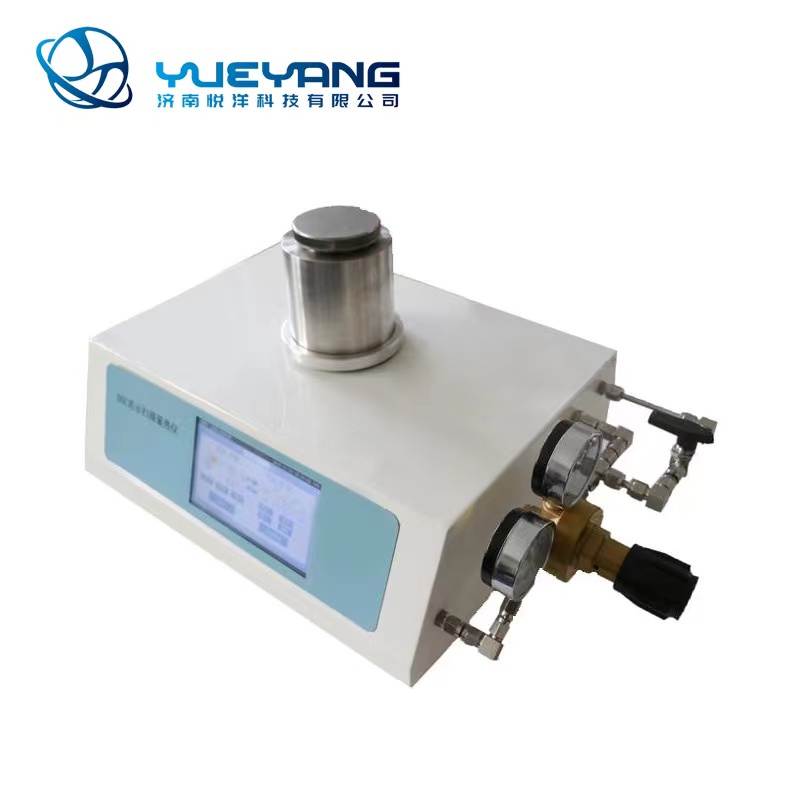

YYP-HP5 Differential scanning calorimeter

Parameters:

- Temperature range: RT-500℃

- Temperature resolution:0.01℃

- Pressure range: 0-5Mpa

- Heating rate: 0.1~80℃/min

- Cooling rate: 0.1~30℃/min

- Constant temperature: RT-500℃,

- Duration of constant temperature: The duration is recommended to be less than 24 hours.

- DSC range: 0~±500mW

- DSC resolution: 0.01mW

- DSC sensitivity: 0.01mW

- Working power: AC 220V 50Hz 300W or other

- Atmosphere control gas: Two-channel gas control by automatic controlled (e.g. nitrogen and oxygen)

- Gas flow:0-200mL/min

- Gas pressure:0.2MPa

- Gas flow accuracy: 0.2mL/min

- Crucible: Aluminium crucible Φ6.6*3mm (Diameter * High)

- Data interface: Standard USB interface

- Display mode: 7-inch touch screen

- Output mode: computer and printer

-

YYP-22D2 Izod Impact Tester

It is used to determine the impact strength (Izod) of non-metallic materials such as rigid plastics, reinforced nylon, glass fiber reinforced plastic, ceramics, cast stone, plastic electrical appliances, insulating materials, etc. Each specification and model has two types: electronic type and pointer dial type: the pointer dial type impact testing machine has the characteristics of high precision, good stability and large measurement range; the electronic impact testing machine adopts the circular grating angle measurement technology, except for In addition to all the advantages of the pointer dial type, it can also digitally measure and display the breaking power, impact strength, pre-elevation angle, lift angle, and the average value of a batch; it has the function of automatic correction of energy loss, and can store 10 sets of historical data information. This series of testing machines can be used for Izod impact tests in scientific research institutions, colleges and universities, production inspection institutes at all levels, material production plants, etc.

-

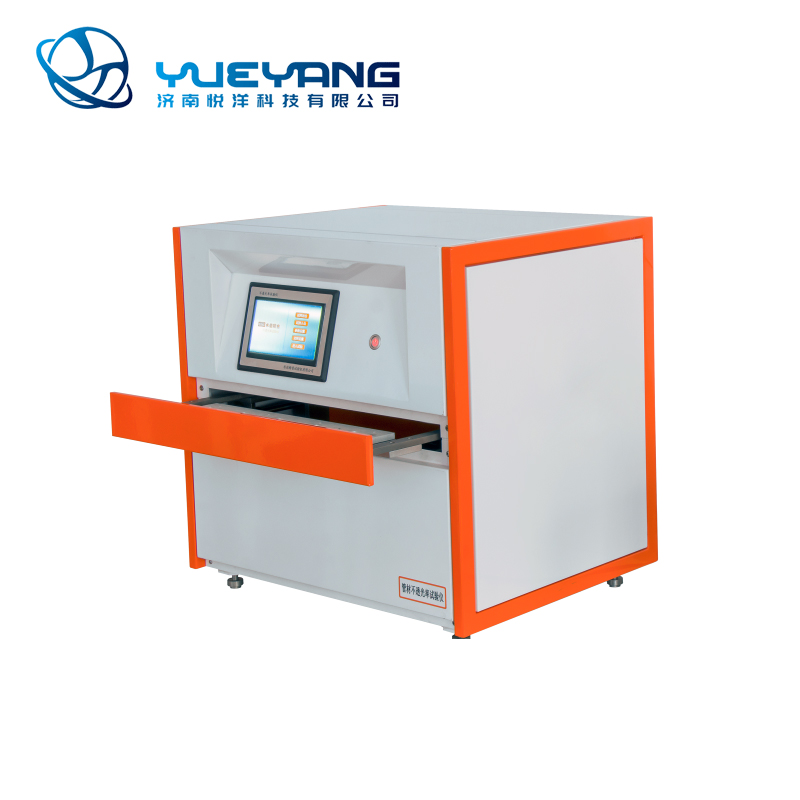

YYP-BTG-A Plastic Pipe Light Transmittance Tester

BTG-A tube light transmittance tester can be used to determine the light transmittance of plastic pipes and pipe fittings (the result is shown as A percentage). The instrument is controlled by industrial tablet computer and operated by touch screen. It has the functions of automatic analysis, recording, storage and display. This series of products are widely used in scientific research institutions, colleges and universities, quality inspection departments, production enterprises.

-

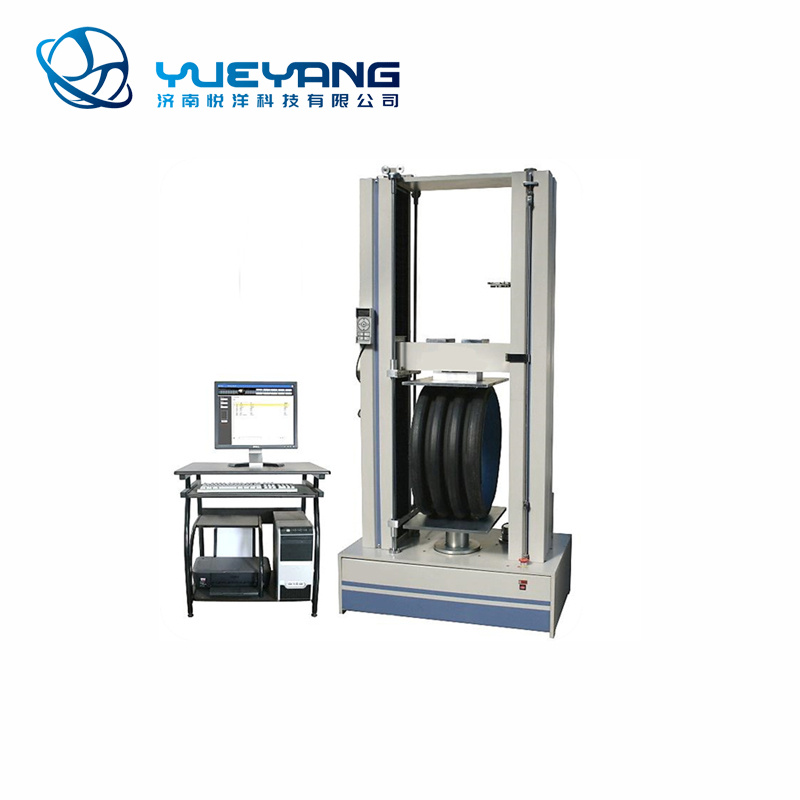

YYP-WDT-W-60B1 Electronic Universal Testing Machine

WDT series micro-control electronic universal testing machine for double screw, host, control, measurement, operation integration structure.

-

YYP-DW-30 Low Temperature Oven

It is composed of freezer and temperature controller. The temperature controller can control the temperature in the freezer at fixed point according to the requirements, and the accuracy can reach ±1 of the indicated value.

-