Textile Testing Instruments

-

YY751B Constant Temperature &humidity Test Chamber

Constant temperature and humidity test chamber is also called high low temperature constant temperature and humidity test chamber, high and low temperature test chamber, programmable can simulate all kinds of temperature and humidity environment, mainly for electronics, electrical, household appliances, automobile spare parts and materials and other products under the condition of constant heat and humidity, high temperature, low temperature and alternating hot and humid test, test the technical specifications of the products and adaptability. Can also be used for all kinds of textiles, fabric before the test of temperature and humidity balance.

-

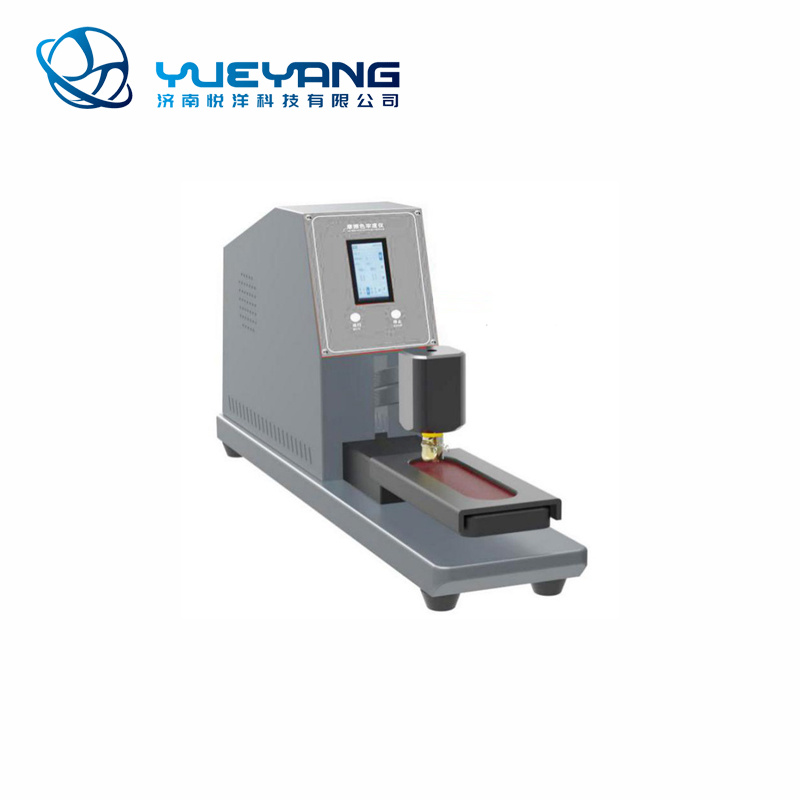

YY571G Friction Fastness Tester (Electric)

Used for friction test to evaluate color fastness in textile, knitwear, leather, electrochemical metal plate, printing and other industries.

-

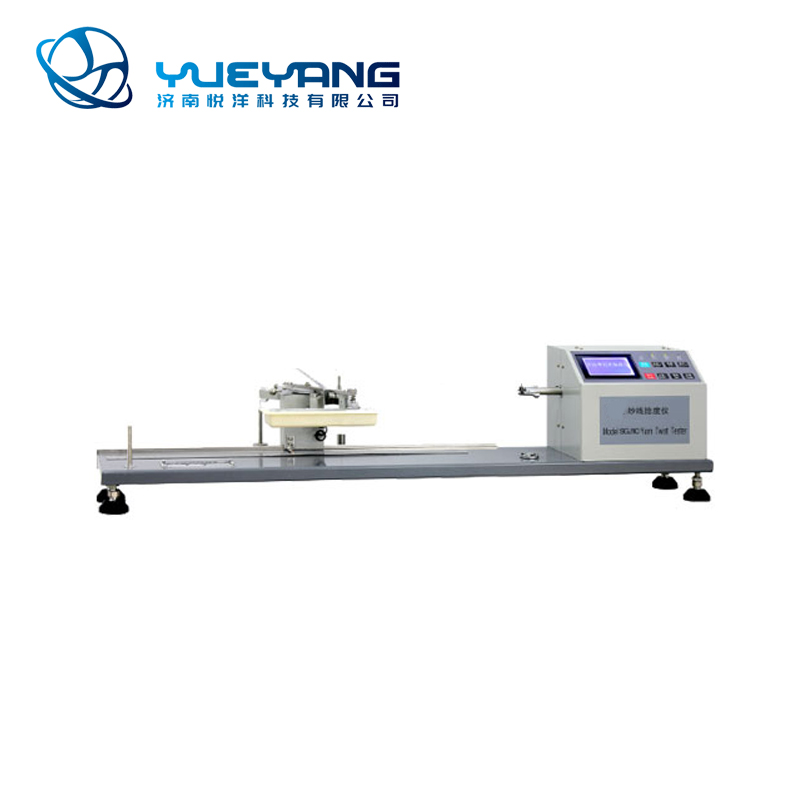

YY331C Yarn Twist Counter

Used for testing twist, twist irregularity, twist shrinkage of all kinds of cotton, wool, silk, chemical fiber, roving and yarn.

-

YY089A Fabric Shrinkage Tester Automatic

Used for measurement of shrinkage and relaxation of all kinds of cotton, wool, hemp, silk, chemical fiber fabrics, clothing or other textiles after washing.

-

YY-L2A Zipper Load Pull Tester

1. The zipper head fixture is specially made with built-in opening structure, which is convenient for customers to use;

2. The positioning block to ensure that the lateral pull of the clamp in the initial clamping is to ensure that the lateral clamping 100°, convenient positioning of the sample;

-

YY021F Electronic Multiwire Strength Tester

Used for testing breaking strength and breaking elongation of raw silk, polyfilament, synthetic fiber monofilament, glass fiber, spandex, polyamide, polyester filament, composite polyfilament and textured filament.

-

YY258A Thermal Resistance Tester For Textiles

Used for testing the thermal resistance of all kinds of fabrics under normal conditions and physiological comfort.

-

(China)YY(B)631-Perspiration color fastness tester

[Scope of application]

It is used for the color fastness test of sweat stains of all kinds of textiles and the determination of the color fastness to water, sea water and saliva of all kinds of colored and colored textiles.

[Relevant standards]

Perspiration resistance: GB/T3922 AATCC15

Seawater resistance: GB/T5714 AATCC106

Water resistance: GB/T5713 AATCC107 ISO105, etc.

[Technical parameters]

1. Weight: 45N± 1%; 5 n plus or minus 1%

2. Splint size

115×60×1.5)mm

115×60×1.5)mm3. Overall size

210×100×160)mm

210×100×160)mm4. Pressure: GB: 12.5kpa; AATCC:12kPa

5. Weight: 12kg

-

(China)YY761A High-low Temperature Test Chamber

High and low temperature test chamber, can simulate a variety of temperature and humidity environment, mainly for electronic, electrical, household appliances, automobile and other product parts and materials under the condition of constant temperature, high temperature, low temperature test, test the performance indicators and adaptability of products.

-

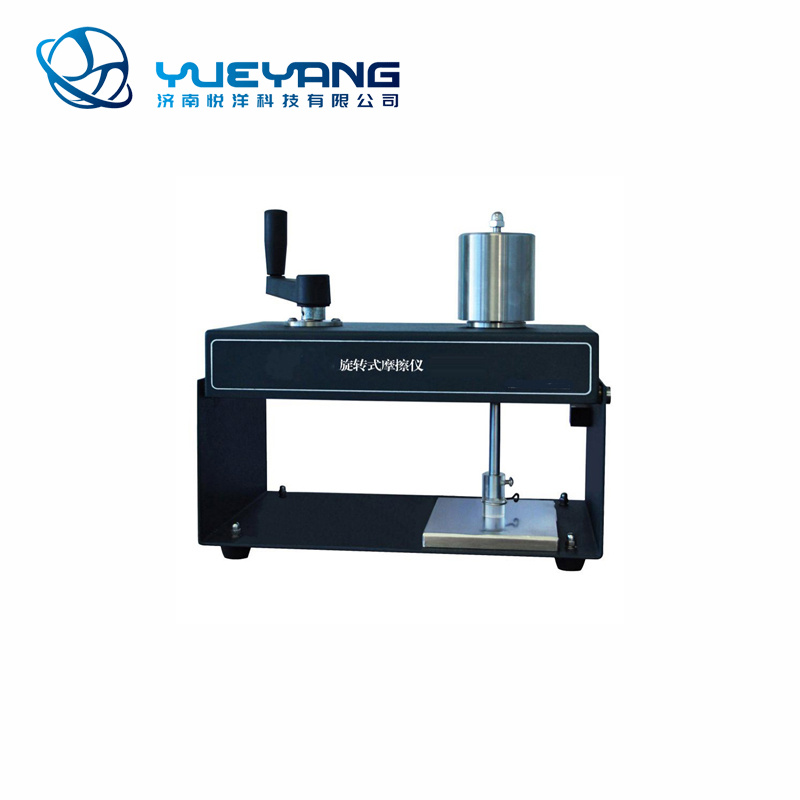

YY571M-III Electric Rotary Tribometer

Used for testing the color fastness to dry and wet rubbing of fabrics, especially printed fabrics. The handle only needs to be rotated clockwise. The instrument friction head should be rubbed clockwise for 1.125 revolutions and then counterclockwise for 1.125 revolutions, and the cycle should be carried out according to this process.

-

YY381 Yarn Examining Machine

Used for testing twist, twist irregularity, twist shrinkage of all kinds of cotton, wool, silk, chemical fiber, roving and yarn.

-

(CHINA)YY607A Plate Type Pressing Instrument

This product is suitable for dry heat treatment of fabrics to evaluate dimensional stability and other heat-related properties of fabrics.

-

YY-L2B Zipper Load Pull Tester

Used for life test of metal, injection molding and nylon zipper under specified load and pull times

-

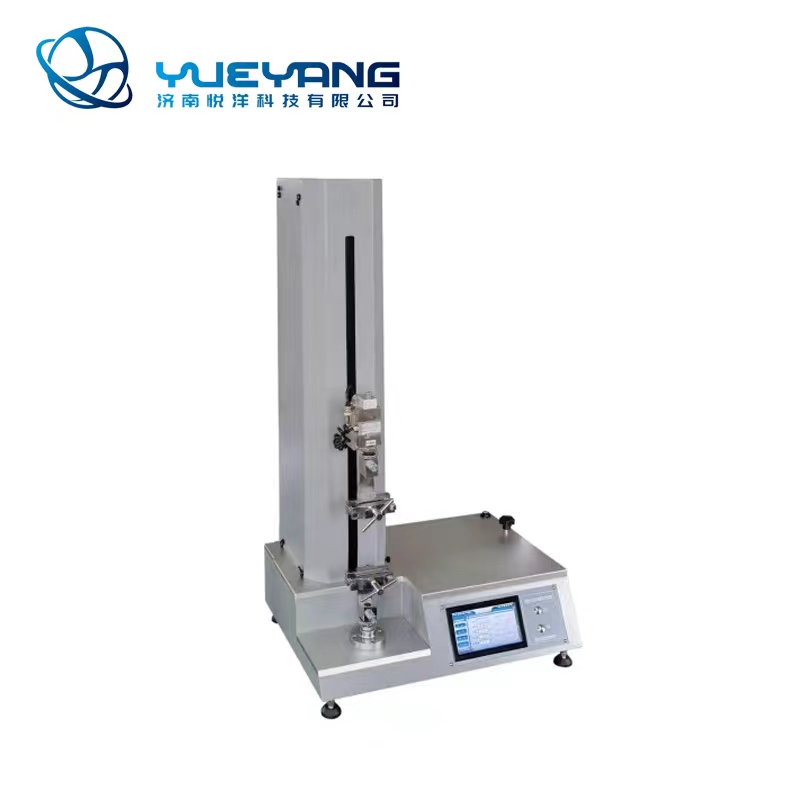

YY021G Electronic Spandex Yarn Strength Tester

Used for testing tensile breaking strength and breaking elongation of spandex, cotton, wool, silk, hemp, chemical fiber, cord line, fishing line, cladded yarn and metal wire. This machine adopts single-chip microcomputer control system, automatic data processing, can display and print Chinese test report.

-

(China)YY(B)902G-Perspiration color fastness oven

[Scope of application]

It is used for the color fastness test of sweat stains of all kinds of textiles and the determination of the color fastness to water, sea water and saliva of all kinds of colored and colored textiles.

[Relevant standards]

Perspiration resistance: GB/T3922 AATCC15

Seawater resistance: GB/T5714 AATCC106

Water resistance: GB/T5713 AATCC107 ISO105, etc.

[Technical parameters]

1. Working mode: digital setting, automatic stop, alarm sound prompt

2. Temperature: room temperature ~ 150℃±0.5℃ (can be customized 250℃)

3. Drying time

0 ~ 99.9)h

0 ~ 99.9)h4. Studio size

340×320×320)mm

340×320×320)mm5. Power supply: AC220V±10% 50Hz 750W

6. Overall size

490×570×620)mm

490×570×620)mm7. Weight: 22kg

-

YY3000A Water Cooling Insolation Climate Aging Instrument (Normal Temperature)

Used for artificial aging test of various textile, dye, leather, plastic, paint, coatings, automotive interior accessories, geotextiles, electrical and electronic products, color building materials and other materials simulated daylight light can also complete the color fastness test to light and weather. By setting the conditions of light irradiance, temperature, humidity and rain in the test chamber, the simulated natural environment required for the experiment is provided to test the performance changes of the material such as color fading, aging, transmittance, peeling, hardening, softening and cracking.

-

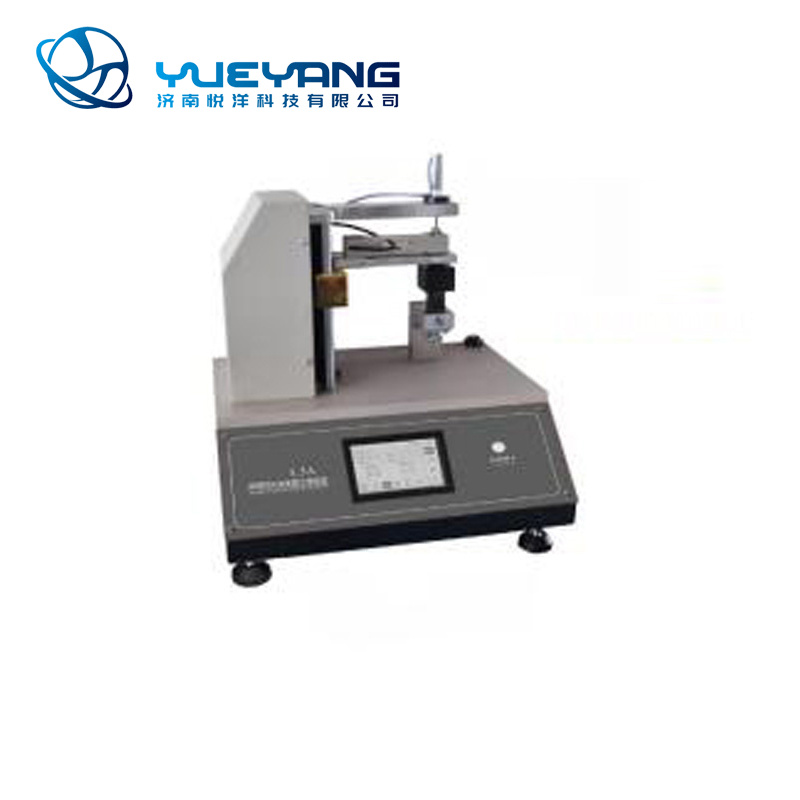

YY605B Ironing Sublimation Colour Fastness Tester

Used for testing sublimation color fastness to ironing of various textiles.

-

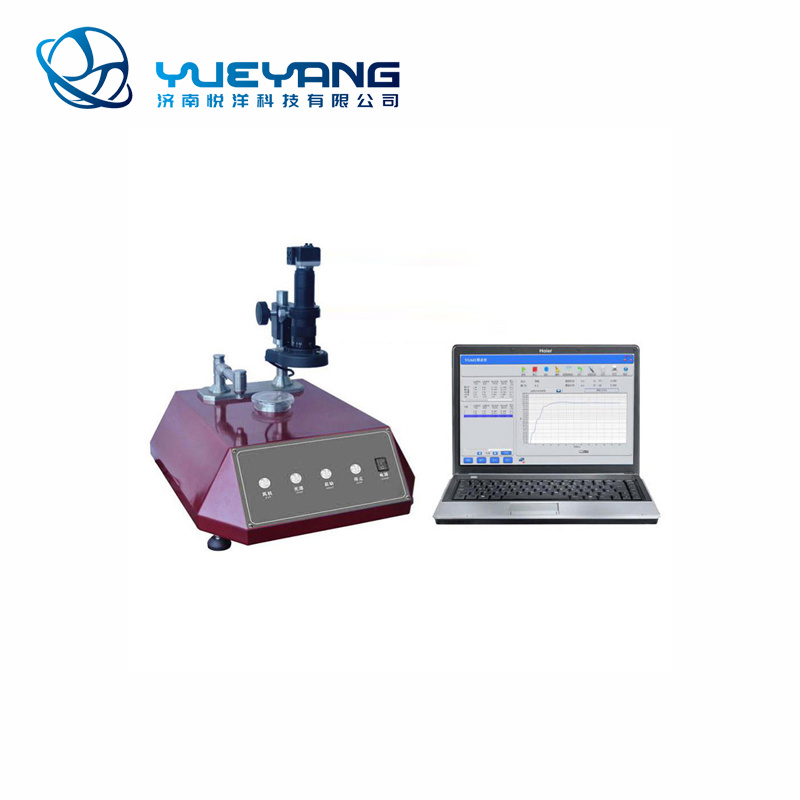

YY641 Smelting Point Instrument

Used in textile, chemical fiber, building materials, medicine, chemical industry and other industries of organic matter analysis, can clearly observe the microscopic and articles under the heating state of the shape, color change and three state transformation and other physical changes.

-

(CHINA)YY607B Plate Type Pressing Instrument

Used for making composite specimen of hot melt bonding lining for garment.

-

YY-L3A Zip Pull head Tensile Strength Tester

Used for testing tensile strength of metal, injection molding, nylon zipper metal pull head under specified deformation.