Rubber&Plastic testing Instruments

-

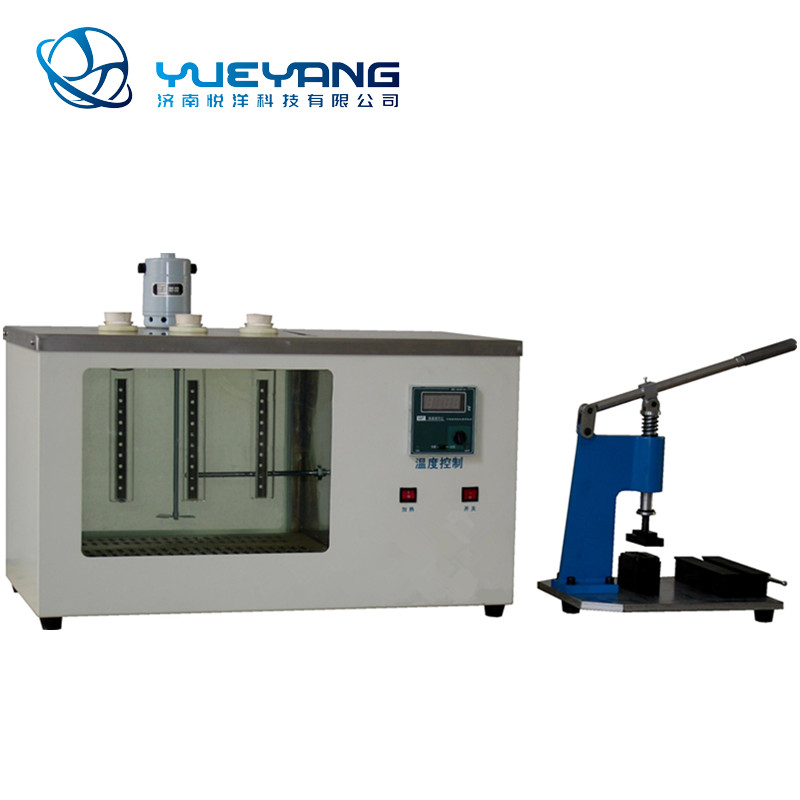

(China)YYPL Environmental Stress Cracking Resistance Tester(ESCR)

I.Applications:

The environmental stress test device is mainly used to obtain the phenomenon of cracking

and destruction of non-metallic materials such as plastics and rubber under the long-term

action of stress below its yield point. The ability of the material to resist environmental stress

damage is measured. This product is widely used in plastics, rubber and other polymer

materials production, research, testing and other industries. The thermostatic bath of this

product can be used as an independent test equipment to adjust the state or temperature of

various test samples.

II.Meeting Standard:

ISO 4599–《 Plastics -Determination of resistance to environmental stress cracking (ESC)-

Bent strip method》

GB/T1842-1999–《Test method for environmental stress-cracking of polyethylene plastics》

ASTMD 1693–《Test method for environmental stress-cracking of polyethylene plastics》

-

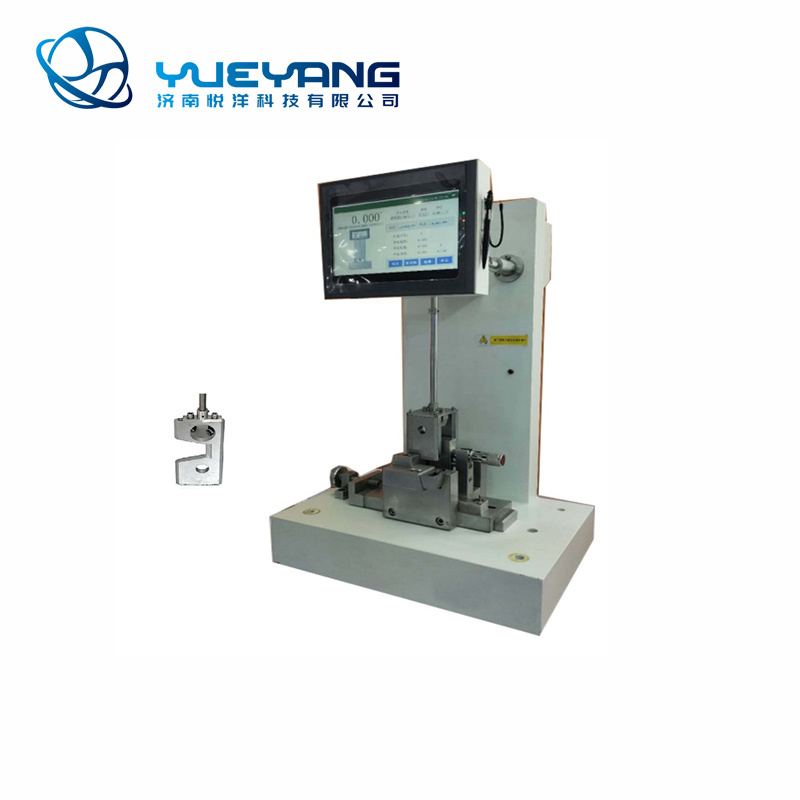

(China)YYP-JC Charpy Impact Tester

Technical standard

The product meets the requirements of test equipment for ENISO179, GB/T1043, ISO9854, GB/T18743 and DIN53453 ,ASTM D 6110 standards.

-

(China)YYP643 Salt Spray Corrosion Test Chamber

YYP643 Salt spray corrosion test chamber with latest PID control is widely

used in

salt spray corrosion test of electroplated parts, paints, coatings, automobile

and motorcycle parts, aviation and military parts, protective layers of metal

materials,

and industrial products such as electric and electronic systems.

-

(China)YY-90 Salt Spray Tester -Touch-screen

I.Use:

Salt spray tester machine is mainly used for surface treatment of various materials, including paint. Electroplating. Inorganic and coated, anodized. After anti-rust oil and other anti-corrosion treatment, the corrosion resistance of its products is tested.

II.Features:

1. Imported digital display controller full digital circuit design, accurate temperature control, long service life, complete testing functions;

2. When working, the display interface is dynamic display, and there is a buzzer alarm to remind the working status; The instrument adopts ergonomic technology, easy to operate, more user-friendly;

3. With automatic/manual water adding system, when the water level is insufficient, it can automatically replenish the water level function, and the test is not interrupted;

4. Temperature controller using touch screen LCD display, PID control error ± 01.C;

5. Double overtemperature protection, insufficient water level warning to ensure safe use.

6. The laboratory adopts the direct steam heating method, the heating rate is fast and uniform, and the standby time is reduced.

7. The precision glass nozzle is evenly diffused by the conical disperser of the spray tower with adjustable fog and fog volume, and naturally falls on the test card, and ensures that there is no crystallization salt blockage.

-

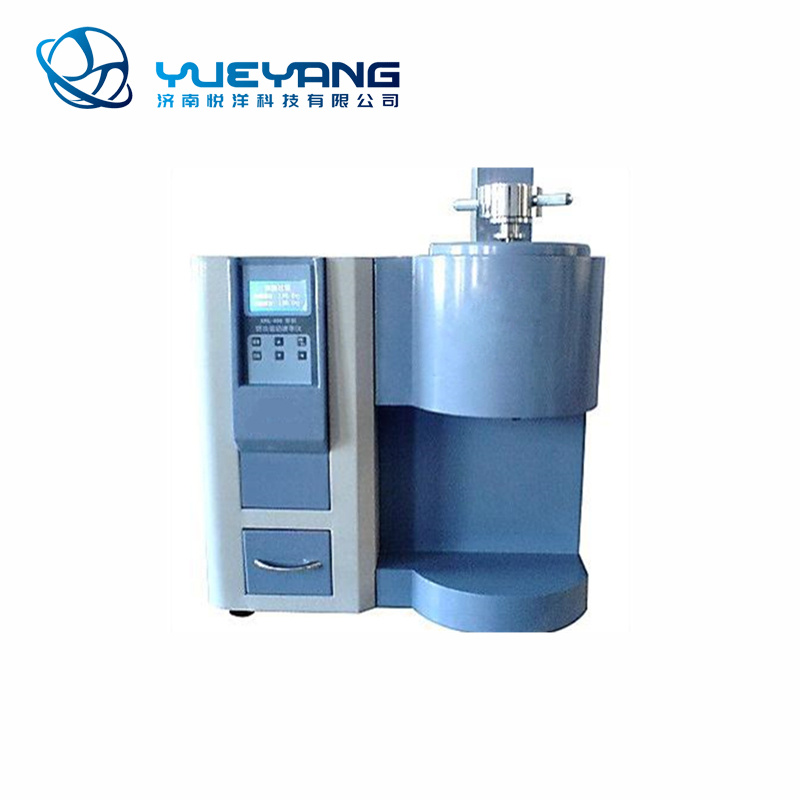

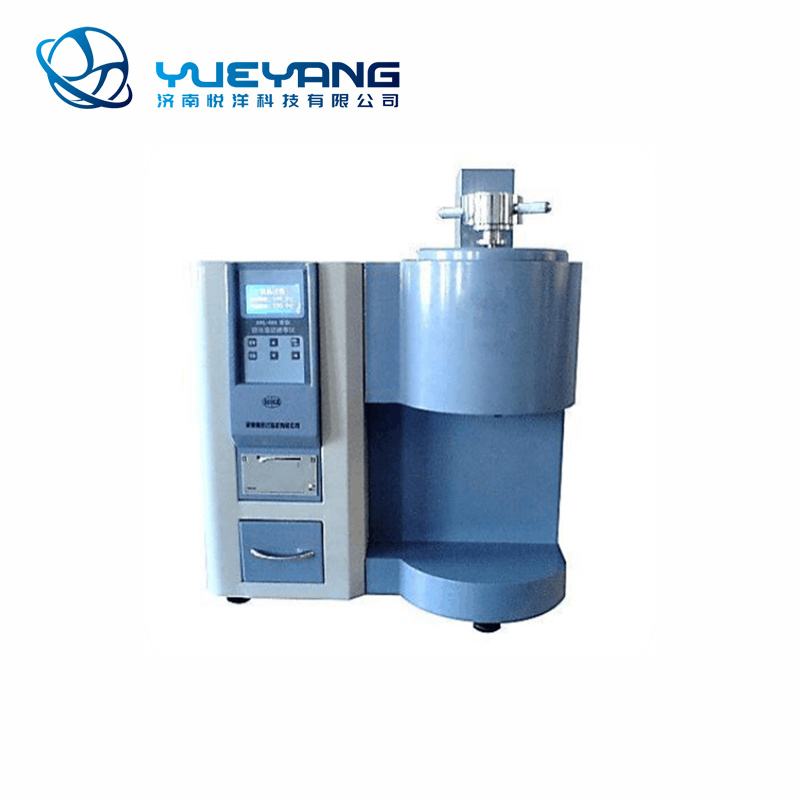

(China)YYP-400BT Melt Flow Indexer

Melt flow Indexer (MFI) refers to the quality or melt volume of the melt through the standard die every 10 minutes at a certain temperature and load, expressed by MFR (MI) or MVR value, which can distinguish the viscous flow characteristics of thermoplastics in the molten state. It is suitable for engineering plastics such as polycarbonate, nylon, fluoroplastic and polyarylsulfone with high melting temperature, and also for plastics with low melting temperature such as polyethylene, polystyrene, polyacrylic, ABS resin and polyformaldehyde resin. Widely used in plastic raw materials, plastic production, plastic products, petrochemical and other industries and related colleges and universities, scientific research units, commodity inspection departments.

-

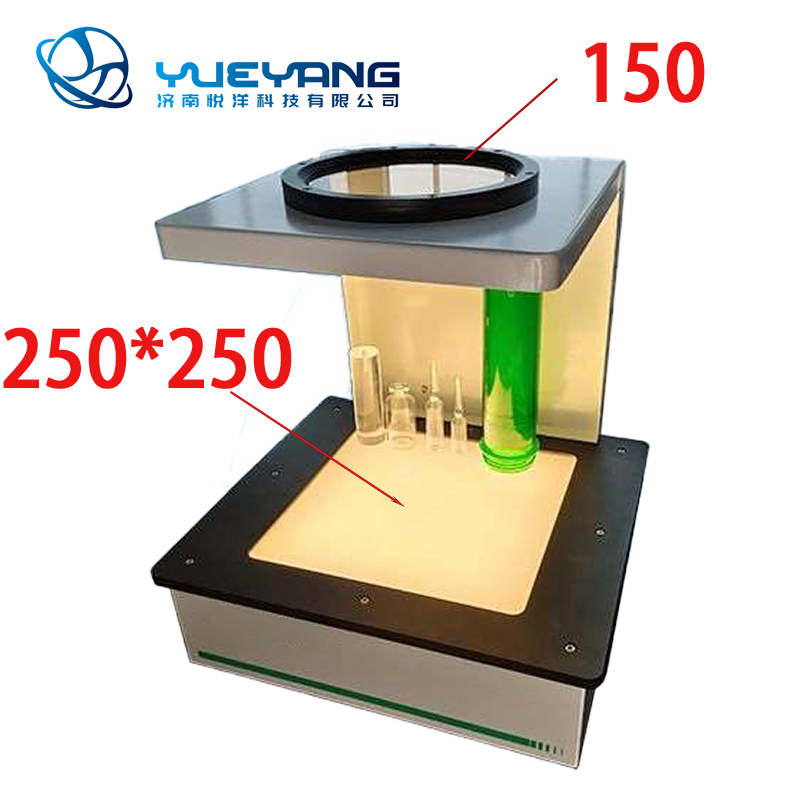

(China)YYPL03 Polariscope Strain Viewer

YYPL03 is a test instrument developed according to the standard《 GB/T 4545-2007 Test method for internal stress in glass bottles》, which is used to test the annealing performance of glass bottles and glass products and analyze the internal stress of

products.

-

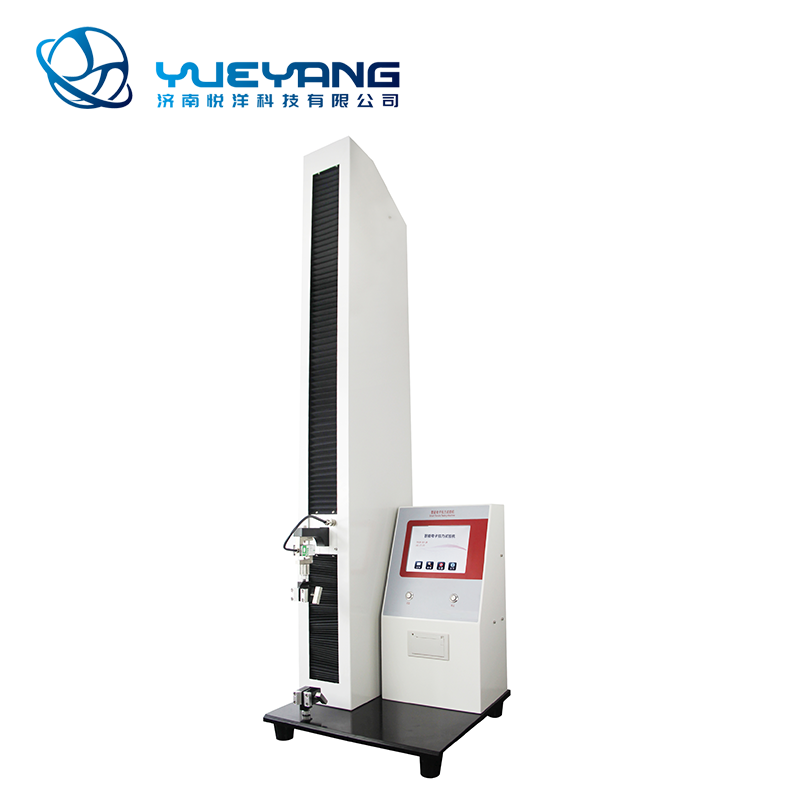

(China)YYP101 Universal Tensile Testing Machine

Technical characteristics:

1.The 1000mm ultra-long test journey

2.Panasonic Brand Servo Motor Testing System

3.American CELTRON brand force measurement system.

4.Pneumatic test fixture

-

(China)YYS-1200 Rain Test Chamber

Function overview:

1. Carry out rain test on the material

2. Equipment standard: Meet the standard GB/T4208, IPX0 ~ IPX6, GB2423.38, GJB150.8A test requirements.

-

(China)YYP-50D2 Simply Supported Beam Impact Tester

Executive standard: ISO179, GB/T1043, JB8762 and other standards. Technical parameters and indicators: 1. Impact speed (m/s): 2.9 3.8 2. Impact energy (J): 7.5, 15, 25, (50) 3. Pendulum angle: 160° 4. Corner radius of impact blade: R=2mm ±0.5mm 5. Jaw fillet radius: R=1mm ±0.1mm 6. The included angle of the impact blade: 30°±1° 7. Jaw spacing: 40mm, 60mm, 70mm, 95mm 8. Display mode: LCD Chinese/English display (with automatic energy loss correction function and storage of historical ... -

(China)YYP-50 Simply Supported Beam Impact Tester

It is used to determine the impact strength (simply supported beam) of non-metallic materials such as rigid plastics, reinforced nylon, glass fiber reinforced plastic, ceramics, cast stone, plastic electrical appliances, and insulating materials. Each specification and model has two types: electronic type and pointer dial type: the pointer dial type impact testing machine has the characteristics of high precision, good stability and large measurement range; the electronic impact testing machine adopts the circular grating angle measurement technology, except for In addition to all the advantages of the pointer dial type, it can also digitally measure and display the breaking power, impact strength, pre-elevation angle, lift angle, and the average value of a batch; it has the function of automatic correction of energy loss, and can store 10 sets of historical data information. This series of testing machines can be used for simply supported beam impact tests in scientific research institutions, colleges and universities, production inspection institutes at all levels, material production plants, etc.

-

YYP-22 Izod Impact Tester

It is used to determine the impact strength (Izod) of non-metallic materials such as rigid plastics, reinforced nylon, glass fiber reinforced plastic, ceramics, cast stone, plastic electrical appliances, insulating materials, etc. Each specification and model has two types: electronic type and pointer dial type: the pointer dial type impact testing machine has the characteristics of high precision, good stability and large measurement range; the electronic impact testing machine adopts the circular grating angle measurement technology, except for In addition to all the advantages of the pointer dial type, it can also digitally measure and display the breaking power, impact strength, pre-elevation angle, lift angle, and the average value of a batch; it has the function of automatic correction of energy loss, and can store 10 sets of historical data information. This series of testing machines can be used for Izod impact tests in scientific research institutions, colleges and universities, production inspection institutes at all levels, material production plants, etc.

-

YYP–JM-G1001B Carbon Black Content Tester

1.New Smart Touch upgrades.

2.With the alarm function at the end of the experiment, the alarm time can be set, and the ventilation time of nitrogen and oxygen can be set. The instrument automatically switches the gas, without manual waiting for the switch

3.Application: It is suitable for the determination of carbon black content in polyethylene, polypropylene and polybutene plastics.

Technical Parameters:

- Temperature range: RT ~1000℃

- 2. Combustion tube size: Ф30mm*450mm

- 3. Heating element: resistance wire

- 4. Display mode: 7-inch wide touch screen

- 5. Temperature control mode: PID programmable control, automatic memory temperature setting section

- 6. Power supply: AC220V/50HZ/60HZ

- 7. Rated power :1.5KW

- 8. Host size: length 305mm, width 475mm, height 475mm

-

YYP-XFX Series Dumbbell Prototype

Summary:

XFX series dumbbell type prototype is a special equipment for preparing standard dumbbell type samples of various non-metallic materials by means of mechanical processing for tensile test.

Meeting Standard:

In line with GB/T 1040, GB/T 8804 and other standards on tensile specimen technology, size requirements.

Technical Parameters:

Model

Specifications

Milling cutter(mm)

rpm

Sample processing

The largest thickness

mm

Size of working plat

(L×W)mm

Power Supply

Dimension

(mm)

Weight

(Kg)

Dia.

L

XFX

Standard

Φ28

45

1400

1~45

400×240

380V ±10% 550W

450×320×450

60

Heighten Increase

60

1~60

-

YYP-400A Melt Flow Indexer

Melt flow indexer is used to characterize the flow performance of thermoplastic polymer in the viscous state of the instrument, used to determine the melt mass flow rate (MFR) and melt volume flow rate (MVR) of thermoplastic resin, both suitable for high melting temperature of polycarbonate, nylon, fluorine plastic, polyaromatic sulfone and other engineering plastics, Also suitable for polyethylene, polystyrene, polypropylene, ABS resin, polyformaldehyde resin and other plastic melting temper... -

(China)YYP-400B Melt Flow Indexer

Melt flow indexer is used to characterize the flow performance of thermoplastic polymer in the viscous state of the instrument, used to determine the melt mass flow rate (MFR) and melt volume flow rate (MVR) of thermoplastic resin, both suitable for high melting temperature of polycarbonate, nylon, fluorine plastic, polyaromatic sulfone and other engineering plastics, Also suitable for polyethylene, polystyrene, polypropylene, ABS resin, polyformaldehyde resin and other plastic melting temper... -

(China)YY 8102 Pneumatic Sample Press

Pneumatic punching machine uses: This machine is used for cutting standard rubber test pieces and similar materials before tensile test in rubber factories and scientific research institutions. Pneumatic control, easy to operate, fast, labor saving. The main parameters of pneumatic punching machine 1.Travel range :0mm ~ 100mm 2.Table size :245mm×245mm 3.Dimensions :420mm×360mm×580mm 4.Working pressure :0.8MPm 5.The surface flatness error of the parallel adjustment device is ±0.1mm Pneumatic p... -

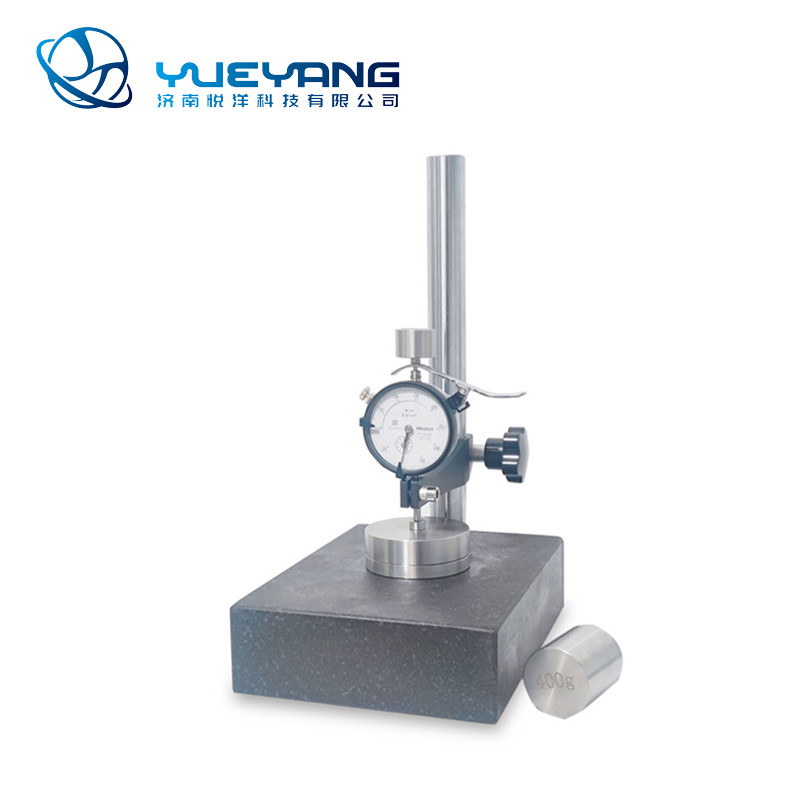

(China)YY F26 Rubber Thickness Gauge

I. Introductions: Plastic thickness meter is composed of marble base bracket and table, used to test the thickness of plastic and film, table display reading, according to the machine. II.Main functions: The thickness of the measured object is the scale indicated by the pointer when the upper and lower parallel disks are clamped. III. Reference Standard: ISO 3034-1975(E), GB/T 6547-1998, ISO3034:1991, GB/T 451.3-2002, ISO 534:1988, ISO 2589:2002(E), QB/T 2709-2005, GB/T2941-2006, ISO 4648-199... -

(China)YY401A Rubber Aging Oven

- Application and characteristics

1.1 Mainly used in scientific research units and factories plasticity materials (rubber, plastic), electrical insulation and other materials aging test. 1.2 The maximum working temperature of this box is 300℃, the working temperature can be from room temperature to the highest working temperature, within this range can be selected at will, after selection can be made by the automatic control system in the box to keep the temperature constant.

-

(China)YY-6005B Ross Flex Tester

I. Introductions: This machine is suitable for right Angle bending test of rubber products, soles, PU and other materials. After stretching and bending the test piece, check the degree of attenuation, damage and cracking. II.Main functions: The sole strip test piece was installed on the ROSS torsional testing machine, so that the notch was directly above the center of the rotating shaft of the ROSS torsional testing machine. The test piece was driven by the ROSS torsional testing machine to c... -

(China)YY-6007B EN Bennewart Flex Tester

I. Introductions: The sole test sample is installed on the EN zigzag testing machine, so that the notch falls on the EN zigzag testing machine is just above the center of the rotating shaft. The EN zigzag testing machine drives the test piece to stretch (90±2)º zigzag on the shaft. After reaching a certain number of tests, the notch length of the test sample is observed to measure. The folding resistance of the sole was evaluated by the incision growth rate. II. Main functions: Test rubber,...