Products

-

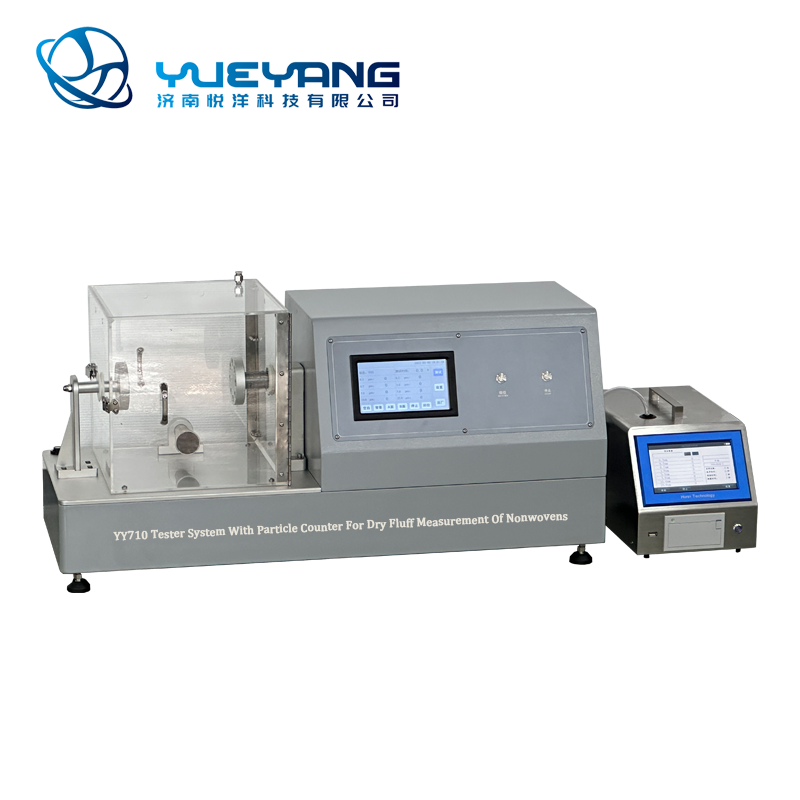

(China)YY710 Gelbo Flex Tester

I.Instrument Applications:

For non-textile fabrics, non-woven fabrics, medical non-woven fabrics in the dry state of the amount

of fiber scraps, raw materials and other textile materials can be dry drop test. The test sample is subjected to a combination of torsion and compression in the chamber. During this twisting process,

air is extracted from the test chamber, and the particles in the air are counted and classified by a

laser dust particle counter.

II.Meet the standard:

GB/T24218.10-2016,

ISO 9073-10,

INDA IST 160.1,

DIN EN 13795-2,

YY/T 0506.4,

EN ISO 22612-2005,

GBT 24218.10-2016 Textile nonwovens test methods Part 10 Determination of dry floc, etc.;

-

(China)Single Side Test Bench PP

Bench size can be customized; Make renderings for free.

-

(China)Central Test Bench PP

Bench size can be customized; Make renderings for free.

-

(China)Single Side Test Bench All Steel

Table top:

Using 12.7mm solid black physical and chemical board for the laboratory,

thickened to 25.4mm around, double-layer exterior garden along the edge,

acid and alkali resistance, water resistance, anti-static, easy to clean.

-

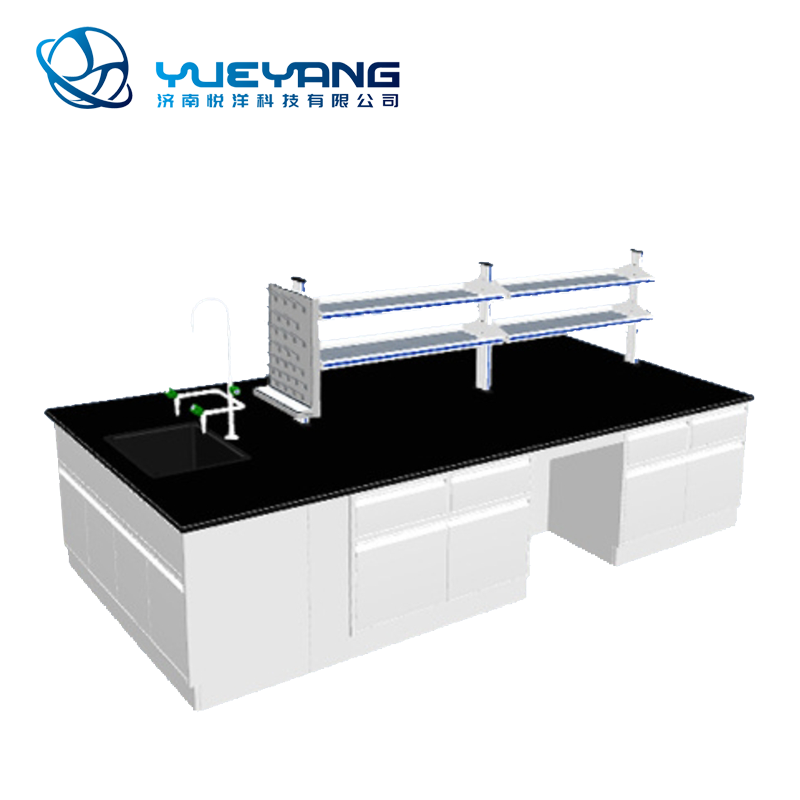

(China)Central Test Bench All Steel

Table top:

Using 12.7mm solid black physical and chemical board for the laboratory, thickened to 25.4mm

around, double-layer exterior garden along the edge, acid and alkali resistance,

water resistance, anti-static, easy to clean.

-

(China)Laboratory Fume Exhaust

Joint:

Adopts corrosion-resistant high-density PP material, can rotate 360 degrees to adjust the direction, easy to disassemble, assemble and clean

Sealing device:

The sealing ring is made of wear-resistant, corrosion-resistant and age-resistant high-density rubber and plastic material

Joint link rod:

Made of stainless steel

Joint tension knob:

The knob is made of corrosion-resistant high-density material, embedded metal nut, stylish and atmospheric appearance.

-

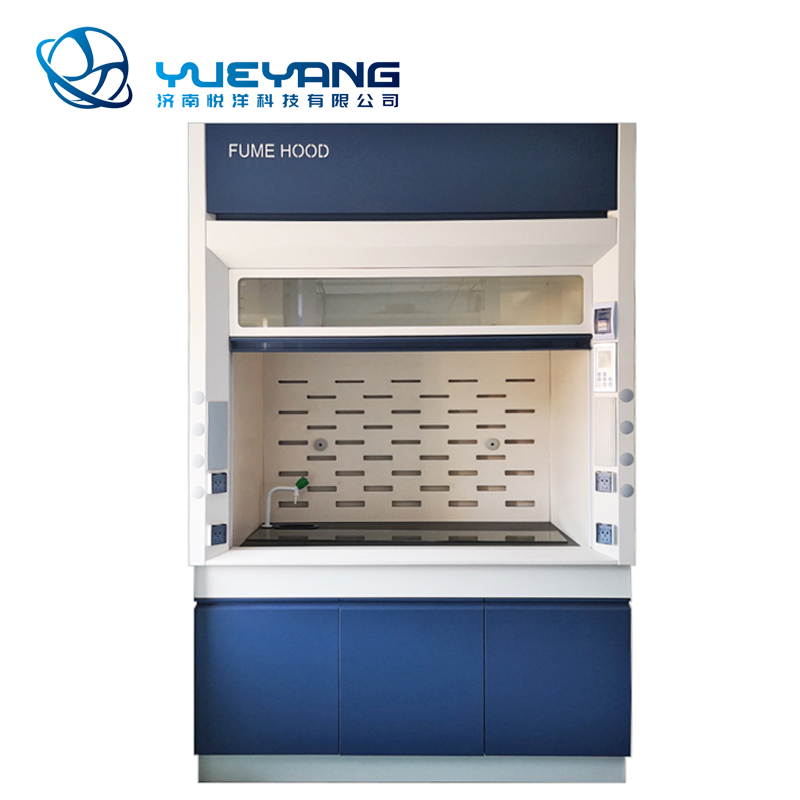

(China)YYT1 Laboratory Fume Hood

I.Material profile:

1. The main side plate, front steel plate, back plate, top plate and lower cabinet body can be made

of 1.0~1.2mm thick steel plate, 2000W imported from Germany

Dynamic CNC laser cutting machine cutting material, bending using automatic CNC bending

machine one at a time bending molding, the surface through epoxy resin powder

Electrostatic line automatic spraying and high temperature curing.

2. The lining plate and the deflector adopts 5mm thick core anti-double special plate with good

anti-corrosion and chemical resistance. The baffle fastener uses PP

High quality material production integrated molding.

3. Move the PP clamp on both sides of the window glass, handle PP into one body, embed 5mm tempered glass, and open the door at 760mm.

Free lifting, sliding door up and down sliding device adopts pulley wire rope structure, stepless

arbitrary stay, sliding door guide device by anti-corrosion polymerization

Made of vinyl chloride.

3. The fixed window frame is made of epoxy resin spraying of steel plate, and 5mm thick tempered glass is embedded in the frame.

4. The table is made of (domestic) solid core physical and chemical board (12.7mm thick) acid and alkali resistance, impact resistance, corrosion resistance, formaldehyde reaches E1 level standards.

5. All the internal connection devices of the connection part need to be hidden and corrosion

resistant, there are no exposed screws, and the external connection devices are resistant

Corrosion of stainless steel parts and non-metallic materials.

6. The exhaust outlet adopts an integrated air hood with the top plate. The diameter of the outlet

is 250mm round hole, and the sleeve is connected to reduce the gas disturbance.

-

(China)YY611D Air Cooled Weathering Color Fastness Tester

Instrument use:

It is used for light fastness, weather fastness and light aging experiment of various textile, printing

and dyeing, clothing, geotextile, leather, plastic and other colored materials. By controlling the light, temperature, humidity, rain and other items in the test chamber, the simulation natural conditions required for the experiment are provided to test the light fastness, weather fastness and light aging performance of the sample.

Meet the standard:

GB/T8427, GB/T8430, ISO105-B02, ISO105-B04 and other standards.

-

(China)YY611B Weathering Color Fastness Tester

Used in textile, printing and dyeing, clothing, automotive interior parts, geotextiles, leather, wood-based panels, wood floors, plastics and other colored materials light fastness, weather resistance and light aging test. By controlling the items such as light irradiance, temperature, humidity and rain in the test chamber, the simulated natural conditions required by the experiment are provided to test the light fastness, weather fastness and photoaging properties of the sample. With light intensity online control; Automatic monitoring and compensation of light energy; Closed-loop control of temperature and humidity; Blackboard temperature loop control and other multi-point adjustment functions. Meets American, European and national standards.

-

(China)YYP-WDT-20A1 Electronic Universal Testing Machine

I.Summarize

WDT series micro control electronic universal testing machine for double screw, host, control, measurement, operation integrated structure. It is suitable for tensile, compression, bending, elastic modulus, shearing, stripping, tearing and other mechanical properties test of all kinds of

(thermosetting, thermoplastic) plastics, FRP, metal and other materials and products. Its software system adopts WINDOWS interface (multiple language versions to meet the use of different

countries and regions), can measure and judge various performance according to national

standards, international standards or user-provided standards, with test parameter setting storage,

test data collection, processing and analysis, display print curve, test report print-out and other functions. This series of testing machine is suitable for material analysis and inspection of engineering plastics, modified plastics, profiles, plastic pipes and other industries. Widely used in scientific research institutions, colleges and universities, quality inspection departments, production enterprises.

Product characteristics

The transmission part of this series of testing machine adopts imported brand AC servo system, deceleration system, precision ball screw, high-strength frame structure, and can be selected

according to the need of large deformation measuring device or small deformation electronic

extender to accurately measure the deformation between the effective marking of the sample. This series of testing machine integrates modern advanced technology in one, beautiful shape, high precision, wide speed range, low noise, easy operation, accuracy up to 0.5, and provides a variety

of specifications/uses of fixtures for different users to choose. This series of products has obtained

the EU CE certification.

II.Executive standard

Meet GB/T 1040, GB/T 1041, GB/T 8804, GB/T 9341, ISO 7500-1, GB 16491, GB/T 17200,

ISO 5893, ASTM D638, ASTM D695, ASTM D790 and other standards.

-

(China)YYP 20KN Electronic Universal Tension Machine

1.Features and uses:

20KN electronic universal material testing machine is a kind of material testing equipment with

domestic leading technology. The product is suitable for tensile, compression, bending, shearing, tearing, stripping and other physical properties test of metal, non-metal, composite materials and products. The measurement and control software uses Windows 10 operating system platform, graphical software interface, flexible data processing mode, modular VB programming method,

safe limit protection and other functions. It also has the function of automatic algorithm generation

and automatic editing of test report, which greatly facilitates and improves the debugging and

system redevelopment ability, and can calculate parameters such as maximum force, yield force,

non-proportional yield force, average stripping force, elastic modulus, etc. It has novel structure, advanced technology and stable performance. Simple operation, flexible, easy maintenance;

Set a high degree of automation, intelligence in one. It can be used for mechanical properties

analysis and production quality inspection of various materials in scientific research departments, colleges and universities and industrial and mining enterprises.

-

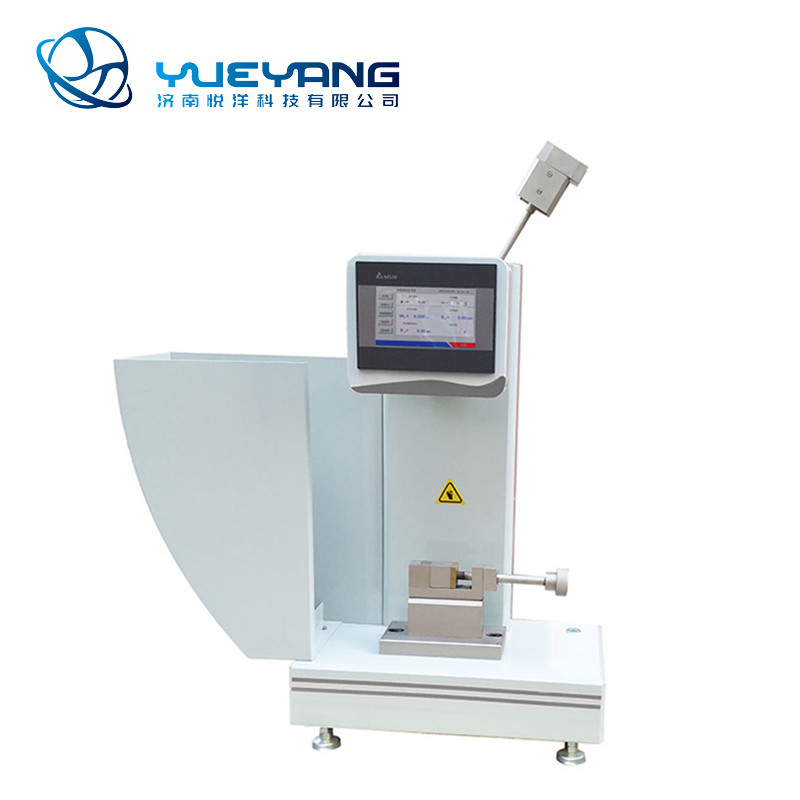

(China)YY- IZIT Izod Impact Tester

I.Standards

l ISO 180

l ASTM D 256

II.Application

Izod method is used to investigate the behavior of specified types of specimen under impact conditions defined and for estimating the brittleness or toughess of specimens within the limitations inherent in the test conditions.

The test specimen, supported as a vertical cantilever beam, is broken by a single impact of a striker, with the line of impact a fixed distance from the specimen clamp and, in the case of notched

specimens, from the centerline of the notch.

-

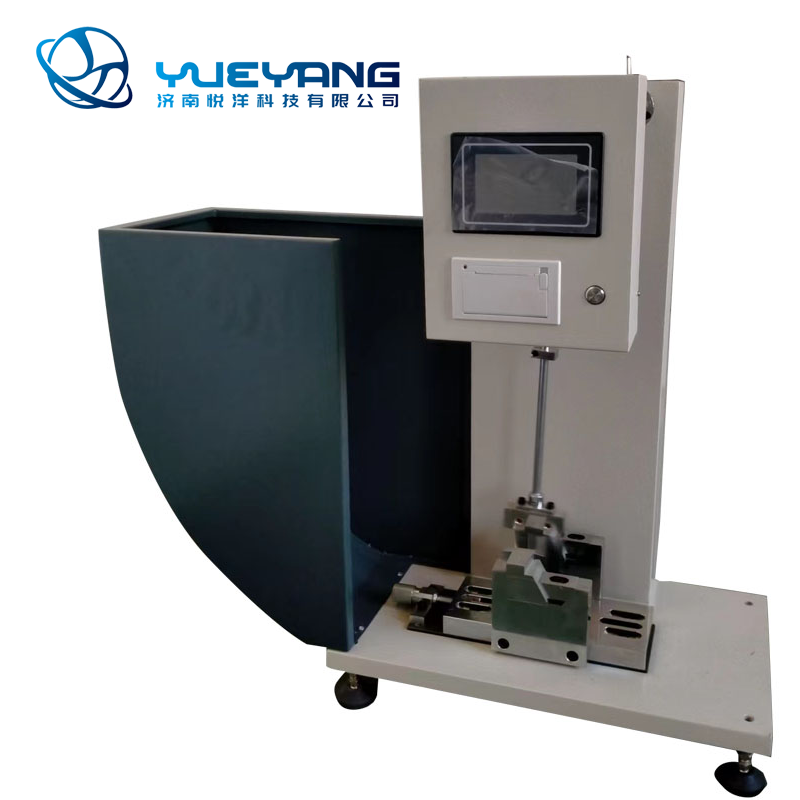

(China)YY22J Izod Charpy Tester

I.Features and uses:

The digital display cantilever beam impact testing machine is mainly used for the determination of

impact toughness of hard plastics, reinforced nylon FRP, ceramics, cast stone, electrical insulation materials and other non-metallic materials. With stable and reliable performance, high precision,

easy to use and other characteristics, can directly calculate the impact energy, save 60 historical

data, 6 kinds of unit transformation, two screen display, can display the practical Angle and Angle

peak or energy, is the chemical industry, scientific research units, colleges and universities, quality inspection departments and professional manufacturers laboratory and other units ideal test

equipment.

-

(China)YY-300F High Frequency Inspection Screening Machine

I. Application:

Used in laboratory, quality inspection room and other inspection departments for particles and

powder materials

Particle size distribution measurement, product impurity content determination analysis.

The test screening machine can realize different screening frequency and screening time according

to different materials through electronic delay device (i.e. timing function) and directional frequency modulator; At the same time, it can also achieve the same direction of the work track and the same vibration duration, frequency and amplitude for the same batch of materials, which can greatly reduce the uncertainty caused by manual screening, thereby reducing the test error, ensuring the consistency of sample analysis data, and improving product quality

Quantity makes standard judgment.

-

(China)YY-S5200 Electronic Laboratory Scale

- Overview:

Precision Electronic scale adopts gold-plated ceramic variable capacitance sensor with concise

and space efficient structure, quick response, easy maintenance, wide weighing range, high precision, extraordinary stability and multiple functions. This series is widely used in laboratory and industry of food, medicine, chemical and metalwork etc. This type of balance, excellent in stability, superior in safety and efficient in operating space, becomes a normally used type in laboratory with cost-effective.

II.Advantage:

1. Adopts gold-plated ceramic variable capacitance sensor;

2. Highly sensitive moisture sensor enable to minimize effect of moisture on operation;

3. Highly sensitive temperature sensor enable to minimize effect of temperature on operation;

4. Various weighing mode: weighing mode, check weighing mode, percent weighing mode, parts counting mode,etc;

5. Various weighing unit conversion functions: grams, carats, ounces and other units of free

switching, suitable for various requirements of the weighing work;

6. Large LCD display panel, bright and clear, provides user with easy operation and read.

7. The balances are characterized by streamline design,high strength,anti-leakage, anti-static

property and corrosion resistance. Suitable for a variety of occasions;

8. RS232 interface for bidirectional communication between balances and computers, printers,

PLCs and other external devices;

-

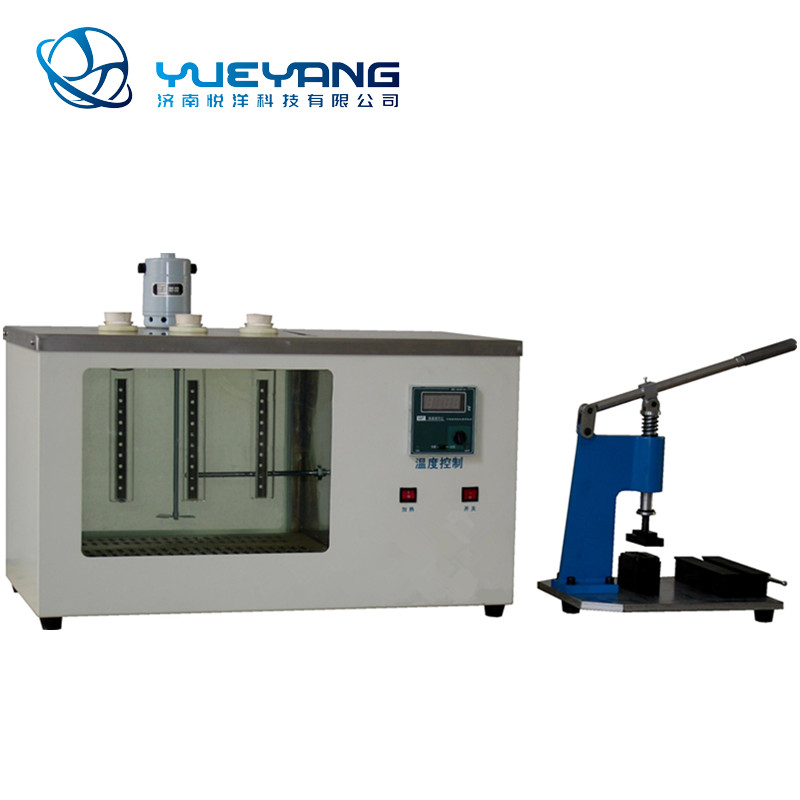

(China)YYPL Environmental Stress Cracking Resistance Tester(ESCR)

I.Applications:

The environmental stress test device is mainly used to obtain the phenomenon of cracking

and destruction of non-metallic materials such as plastics and rubber under the long-term

action of stress below its yield point. The ability of the material to resist environmental stress

damage is measured. This product is widely used in plastics, rubber and other polymer

materials production, research, testing and other industries. The thermostatic bath of this

product can be used as an independent test equipment to adjust the state or temperature of

various test samples.

II.Meeting Standard:

ISO 4599–《 Plastics -Determination of resistance to environmental stress cracking (ESC)-

Bent strip method》

GB/T1842-1999–《Test method for environmental stress-cracking of polyethylene plastics》

ASTMD 1693–《Test method for environmental stress-cracking of polyethylene plastics》

-

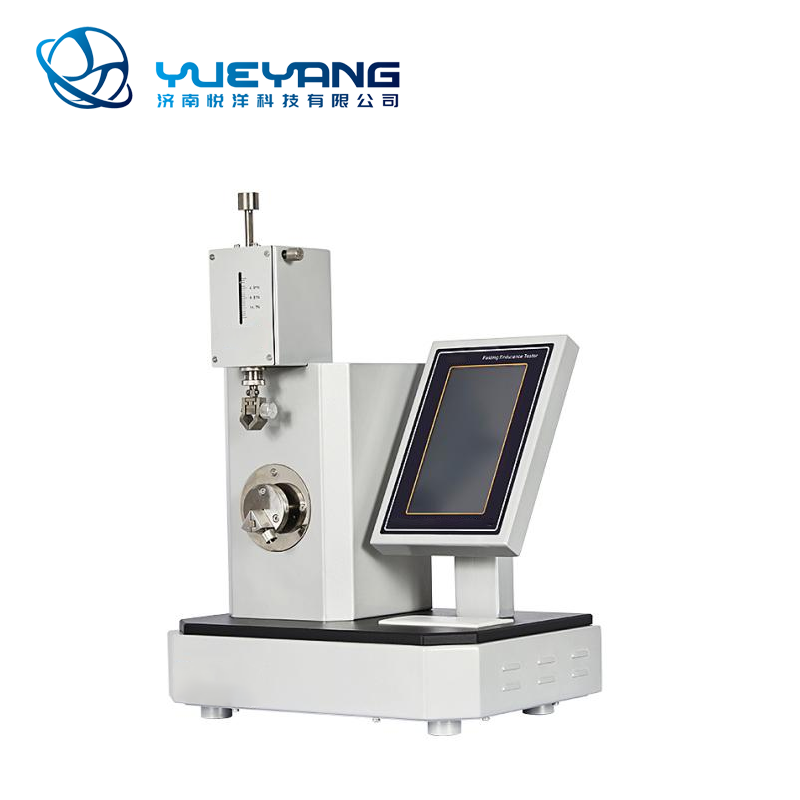

(China)YYP111A Folding Resistance Tester

- Applications:

The folding resistance tester is a test tool used to test the folding fatigue performance of thin

materials such as paper, through which the folding resistance and folding resistance can be tested.

II.Range of Application

1.0-1mm paper, cardboard, cardboard

2.0-1mm glass fiber, film, circuit board, copper foil, wire, etc

III.Equipment characteristics:

1.High closed loop stepper motor, rotation Angle, folding speed accurate and stable.

2.ARM processor, improve the corresponding speed of the instrument, the calculation data is

accurate and fast.

3.Automatically measures, calculates and prints test results, and has the function of data saving.

4.standard RS232 interface, with microcomputer software for communication (purchased separately).

IV. Meeting Standard:

GB/T 457,QB/T1049,ISO 5626,ISO 2493

-

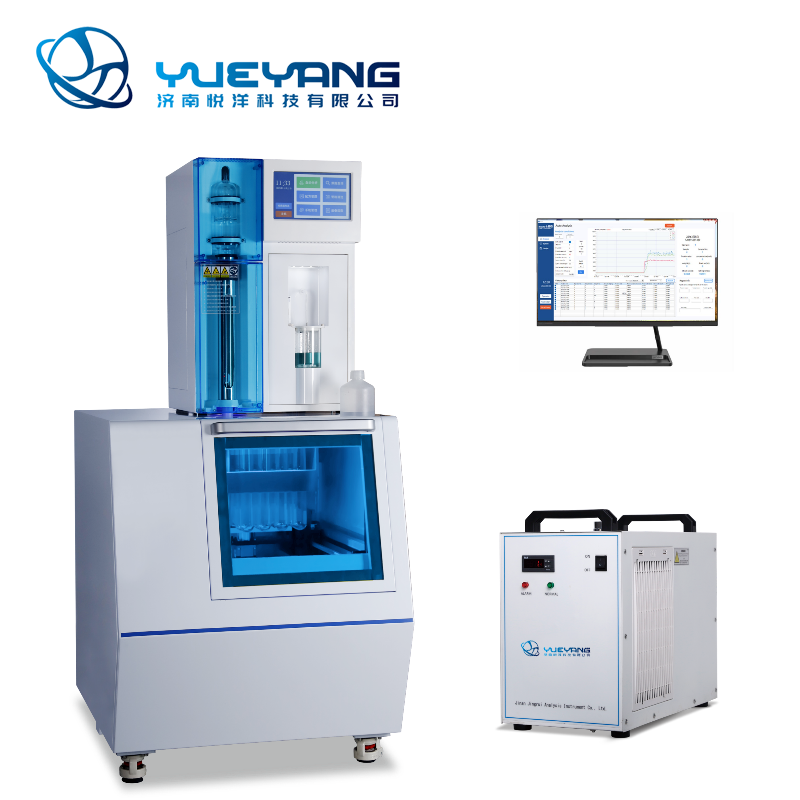

(China)YY9870B Automatic Kjeldahl nitrogen analyzer

Summary:

Kjeldahl method is a classical method for nitrogen determination. Kjeldahl method is widely used to determine nitrogen compounds in soil, food, animal husbandry, agricultural products, feed and

other products. The sample determination by this method requires three processes: sample

digestion, distillation separation and titration analysis

The company is one of the founding units of the national standard of “GB/T 33862-2017

full (semi-) automatic Kjeldahl nitrogen analyzer”, so the products developed and produced by

Kjeldahl nitrogen analyzer meet the “GB” standard and related international standards.

-

(China)YY9870A Automatic Kjeldahl nitrogen analyzer

Summary:

Kjeldahl method is a classical method for nitrogen determination. Kjeldahl method is widely used to determine nitrogen compounds in soil, food, animal husbandry, agricultural products, feed and

other products. The sample determination by this method requires three processes: sample

digestion, distillation separation and titration analysis

The company is one of the founding units of the national standard of “GB/T 33862-2017 full

(semi-) automatic Kjeldahl nitrogen analyzer”, so the products developed and produced by

Kjeldahl nitrogen analyzer meet the “GB” standard and related international standards.

-

(China)YY9870 Automatic Kjeldahl nitrogen analyzer

Summary:

Kjeldahl method is a classical method for nitrogen determination. Kjeldahl method is widely used

to determine nitrogen compounds in soil, food, animal husbandry, agricultural products, feed and

other products. The sample determination by this method requires three processes: sample

digestion, distillation separation and titration analysis

The company is one of the founding units of the national standard of “GB/T 33862-2017 full

(semi-) automatic Kjeldahl nitrogen analyzer”, so the products developed and produced by

Kjeldahl nitrogen analyzer meet the “GB” standard and related international standards.