Products

-

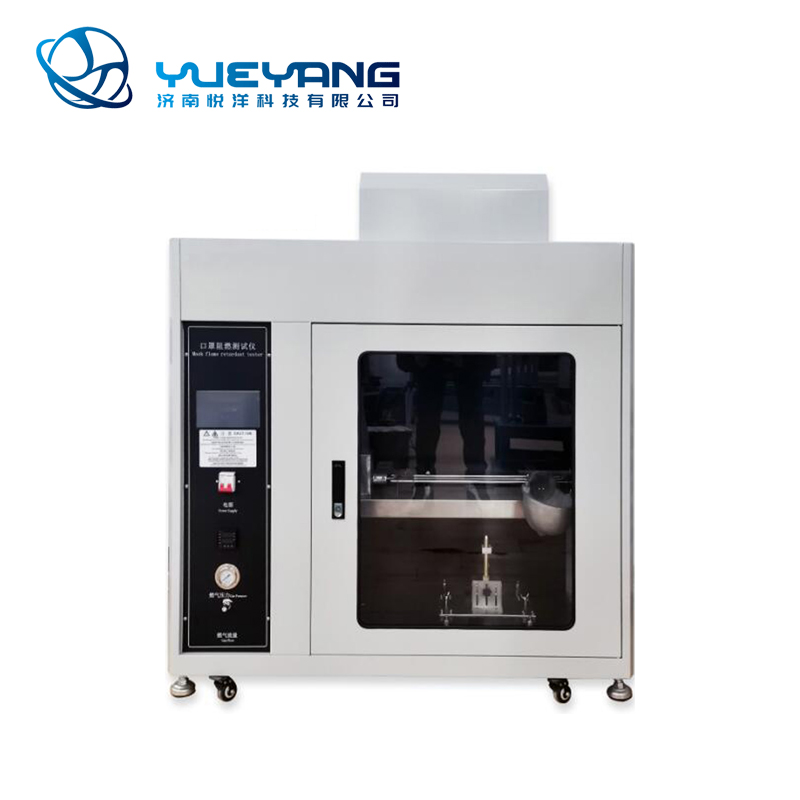

YYT-07B Respirator Flame Retardant Tester

The flame retardant tester for respirator is developed according to gb2626 respiratory protective equipment, which is used to test the fire resistance and flame retardant performance of respirators. The applicable standards are: gb2626 respiratory protective articles, gb19082 technical requirements for disposable medical protective clothing, gb19083 technical requirements for medical protective masks, and gb32610 technical specification for daily protective masks Yy0469 medical surgical mask,... -

YYT-07A Fabric Flame Retardant Tester

1. Ambient temperature: – 10 ℃~ 30 ℃ 2. Relative humidity: ≤ 85% 3. Power supply voltage and power: 220 V ± 10% 50 Hz, power less than 100 W 4. Touch screen display / control, touch screen related parameters: a. Size: 7 “effective display size: 15.5cm long and 8.6cm wide; b. Resolution: 480 * 480 c. Communication interface: RS232, 3.3V CMOS or TTL, serial port mode d. Storage capacity: 1g e. Using pure hardware FPGA drive display, “zero” start-up time, power on can ru... -

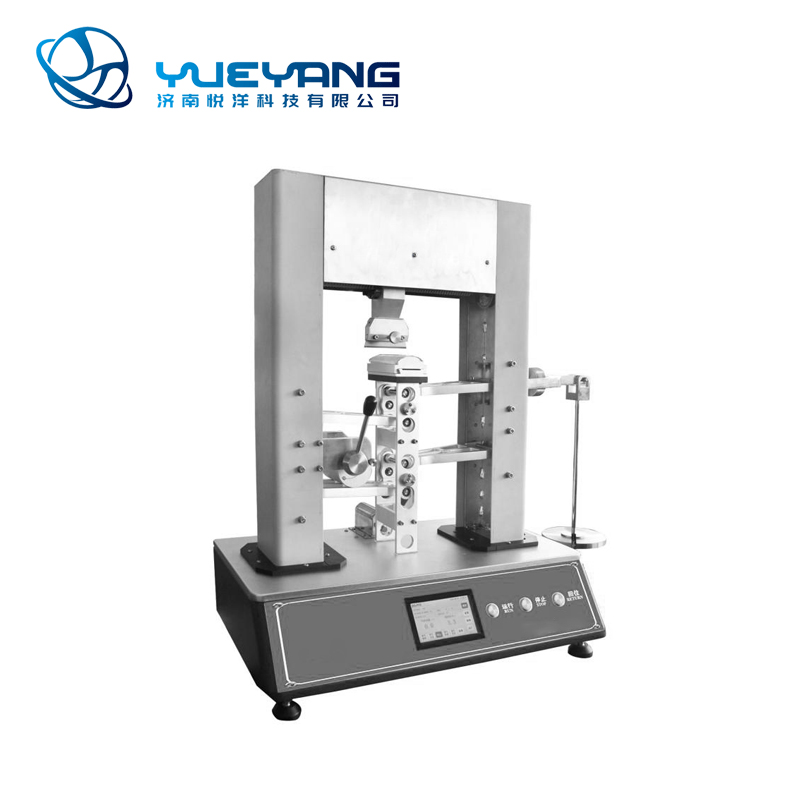

YY6001A Protective Clothing Cutting Ability Tester (against sharp objects)

Used for testing the performance of materials and components in the design of protective clothing. The amount of vertical (normal) force required to cut through the test specimen by cutting the blade over a fixed distance. EN ISO 13997 1. Color touch screen display, control, Chinese and English interface, menu operation mode; 2.Servo motor drive, high precision ball screw control speed; 3. Imported high precision bearings, small friction, high precision; 4. No radial swing, no runout and v... -

YYT-T453 Protective Clothing Anti-Acid And Alkali Test System

The conductivity method and automatic timing device are used to test the penetration time of the fabric protective clothing for acid and alkali chemicals. The sample is placed between the upper and lower electrode sheets, and the conductive wire is connected to the upper electrode sheet and is in contact with the upper surface of the sample. When the penetrating phenomenon occurs, the circuit is turned on and the timing stops. The instrument structure mainly includes the following parts: 1. U... -

YYT-T453 Protective clothing anti-acid and alkali test system

This instrument is specially designed to measure the liquid repellent efficiency of fabric protective clothing fabrics for acid and alkali chemicals. 1. Semi-cylindrical plexiglass transparent tank, with an inner diameter of (125±5) mm and a length of 300 mm. 2. The diameter of the injection needle hole is 0.8mm; the needle tip is flat. 3. Automatic injection system, continuous injection of 10mL reagent within 10s. 4. Automatic timing and alarm system; LED display test time, accuracy 0.1S. 5.... -

YYT-T453 Protective Clothing Acid And Alkali Resistance Test System Operation Manual

This instrument is used to test the hydrostatic pressure resistance of fabric protective clothing for acid and alkali chemicals. The hydrostatic pressure value of the fabric is used to express the resistance of the reagent through the fabric. 1. Liquid adding barrel 2. Sample clamp device 3. Liquid drain needle valve 4. Waste liquid recovery beaker Appendix E of “GB 24540-2009 Protective Clothing Acid-base Chemical Protective Clothing” 1. Test accuracy: 1Pa 2. Test range: ... -

YYPL1-00 Laboratory Rotary Digester

YYPL1-00 Laboratory Rotary Digester ( cooking ,Laboratory digester for wood) is simulated in the production of steam ball working principle design, the pot body to make circumferential motion, make slurry for well mixed, suitable for papermaking laboratory to acid or alkali Zheng cook a variety of fiber raw material, according to different requirements of the process can be expected to plant size, thus for the production of process of the development of cooking process provides a basis. Can a... -

YY-PL15 Lab Pulp Screen

PL15 Lab Pulp Screen is the pulping papermaking laboratory uses the pulp screen, reduces in the paper pulp suspending liquid in the papermaking experiment not to conform to the technological requirement impurity quantity, obtains the pure good thick liquid. This machine is the size for 270×320 the plate-type vibration pulp screen, may choose and match the different specification slit the lamina cribrosa, it is hits the good paper pulp, uses the mode of vibrations vacuum take-off function, car... -

YY-PL27 Type FM Vibration-Type Lab-Potcher

YY-PL27 Type FM Vibration-Type Lab-Potcher is used to simulate the production process rinse pulp of the experiment, can accomplish the pulp bleaching front wash, after washing, bleaching pulp bleaching process. The machine features: small size, low frequency vibration frequency from sieve continuously adjusts to high frequency, disassembled, easy to operate, can according to the pulp choose different frequencies in order to achieve the best effect for production, offer the most reliable exper... -

Double pieces semi-automatic nailing machine of Color box(Four servo)

Main technical parameters Mechanical model (the data in brackets are actual paper) 2100(1600) 2600(2100) 3000(2500) The max paper(A+B)×2(mm) 3200 4200 5000 The min paper(A+B)×2(mm) 1060 1060 1060 The max length of carton A(mm) 1350 1850 2350 The min length of carton A(mm) 280 280 280 The max width of carton B(mm) 1000 1000 1200 The min width of carton B(mm) 140 140 140 The max height of paper (C+D+C)(mm) 2500 2500... -

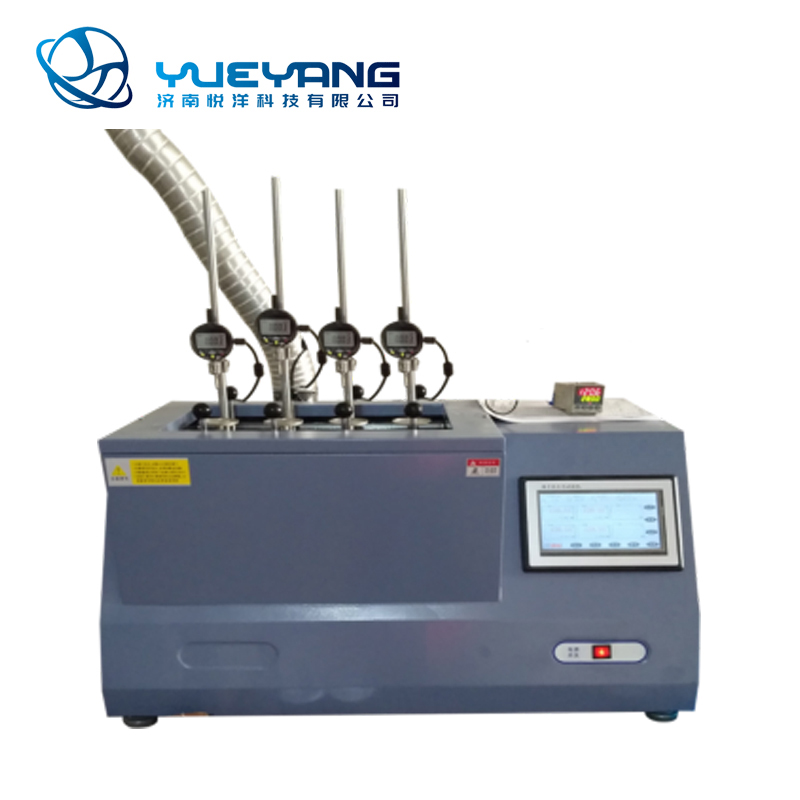

YYP–HDT VICAT TESTER

The HDT VICAT TESTER is used to determine Heating deflection and Vicat softening temperature of the plastic, rubber etc. thermoplastic , It is widely used in the production, research and teaching of plastic raw materials and products. The series of instruments are compact in structure, beautiful in shape, stable in quality, and have the functions of discharging odor pollution and cooling. Using advanced MCU (multi-point micro-control unit) control system, automatic measurement and control of temperature and deformation, automatic calculation of test results, can be recycled to store 10 sets of test data. This series of instruments have a variety of models to choose from: automatic LCD display, automatic measurement; micro-control can connect computers, printers, controlled by computers, test software WINDOWS Chinese (English) interface, with automatic measurement, real-time curve, data storage, printing and other functions.

Technical parameter

1. Temperature control range: room temperature to 300 degrees centigrade.

2. heating rate: 120 C /h [(12 + 1) C /6min]

50 C /h [(5 + 0.5) C /6min]

3. maximum temperature error: + 0.5 C

4. deformation measurement range: 0 ~ 10mm

5. maximum deformation measurement error: + 0.005mm

6. the accuracy of deformation measurement is: + 0.001mm

7. sample rack (test station):3, 4, 6 (optional)

8. support span: 64mm, 100mm

9. the weight of the load lever and the pressure head (needles): 71g

10. heating medium requirements: methyl silicone oil or other media specified in the standard (flash point greater than 300 degrees Celsius)

11. cooling mode: water below 150 degrees Celsius, natural cooling at 150 C.

12. has upper limit temperature setting, automatic alarm.

13. display mode: LCD display, touch screen

14. The test temperature can be displayed, the upper limit temperature can be set, the test temperature can be automatically recorded, and the heating can be stopped automatically after the temperature reaches the upper limit.

15. deformation measurement method: special high-precision digital dial gauge + automatic alarm.

16. It has an automatic smoke removal system, which can effectively inhibit the smoke emission and maintain a good indoor air environment at all times.

17. power supply voltage: 220V + 10% 10A 50Hz

18. heating power: 3kW

-

YY–UTM-01A Universal Material Testing Machine

This machine is used for metal and non-metal (including composite materials) tensile, compression, bending, shear, peeling, tearing, load, relaxation, reciprocating and other items of static performance testing analysis research, can automatically obtain REH, Rel, RP0.2, FM, RT0.5, RT0.6, RT0.65, RT0.7, RM, E and other test parameters. And according to GB, ISO, DIN, ASTM, JIS and other domestic and international standards for testing and provide data.

-

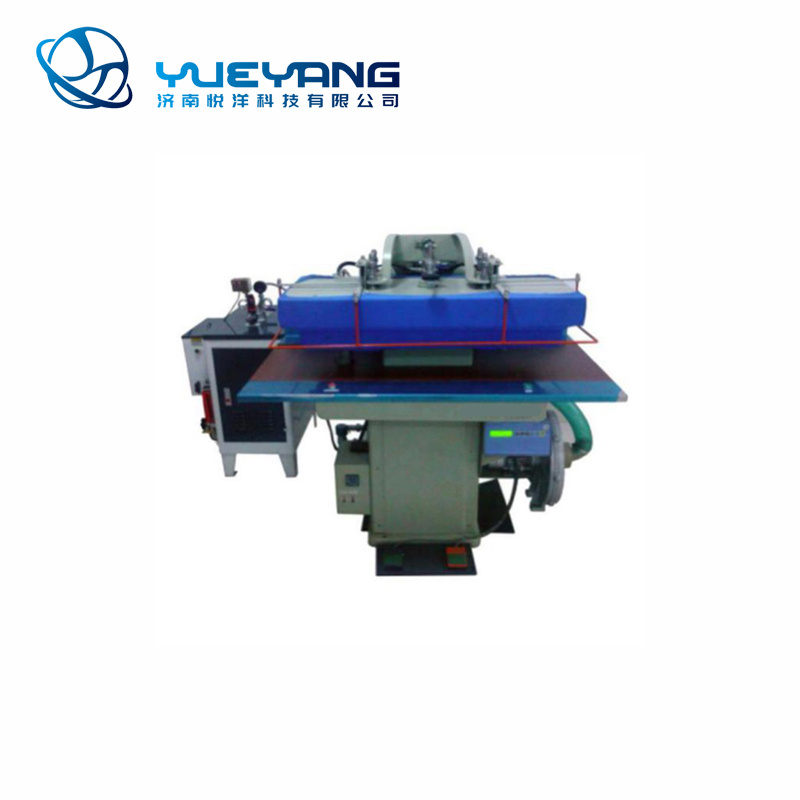

YY605M Ironing Sublimation Colour Fastness Tester

Used for testing color fastness to ironing and sublimation of all kinds of colored textiles.

-

(China)YY(B)902G-Perspiration color fastness oven

[Scope of application]

It is used for the color fastness test of sweat stains of all kinds of textiles and the determination of the color fastness to water, sea water and saliva of all kinds of colored and colored textiles.

[Relevant standards]

Perspiration resistance: GB/T3922 AATCC15

Seawater resistance: GB/T5714 AATCC106

Water resistance: GB/T5713 AATCC107 ISO105, etc.

[Technical parameters]

1. Working mode: digital setting, automatic stop, alarm sound prompt

2. Temperature: room temperature ~ 150℃±0.5℃ (can be customized 250℃)

3. Drying time

0 ~ 99.9)h

0 ~ 99.9)h4. Studio size

340×320×320)mm

340×320×320)mm5. Power supply: AC220V±10% 50Hz 750W

6. Overall size

490×570×620)mm

490×570×620)mm7. Weight: 22kg

-

(China)YY751A Constant Temperature and humidity chamber

Constant temperature and humidity chamber is also called high and low temperature and humidity chamber, programmable high and low temperature chamber, can simulate a variety of temperature and humidity environment, mainly for electronic, electrical, household appliances, automobiles and other product parts and materials in the constant wet and heat condition, high temperature, low temperature and alternating wet and heat test, test the performance indicators and adaptability of products. It can also be used for all kinds of textiles and fabrics to adjust temperature and humidity before the test.

-

YY001-Button Tensile Strength Tester (pointer display)

It is mainly used for testing the stitching strength of buttons on all kinds of textiles. Fix the sample on the base, hold the button with a clamp, lift the clamp to disengage the button, and read the required tension value from the tension table. Is to define the responsibility of the garment manufacturer to ensure that buttons, buttons and fixtures are properly secured to the garment to prevent the buttons from leaving the garment and creating a risk of being swallowed by the infant. Therefore, all buttons, buttons and fasteners on garments must be tested by a button strength tester.

-

YY981B Rapid Extractor For Fiber Grease

Used for rapid extraction of various fiber grease and determination of sample oil content.

-

YY607Z Automatic Steam Ironing Shrinkage Tester

1. Pressure mode: pneumatic

2. Air pressure adjustment range: 0– 1.00Mpa; + / – 0.005 MPa

3. Ironing die surface size: L600×W600mm

4. Steam injection mode: upper mold injection type -

(China)YY-SW-24AC-Color fastness to washing tester

[Scope of application]

It is used for testing the colour fastness to washing, dry cleaning and shrinkage of various textiles, and also for testing the colour fastness to washing of dyes.

[Related standards]

AATCC61/1 A / 2 A / 3 A / 4 A / 5 A, JIS L0860/0844, BS1006, GB/T3921 1/2/3/4/5, ISO105C01/02/03/04/05/06/08, etc

[Technical parameters]

1. Test cup capacity: 550ml (φ75mm×120mm) (GB, ISO, JIS and other standards)

1200ml (φ90mm×200mm) (AATCC standard)

12 PCS (AATCC) or 24 PCS (GB, ISO, JIS)

2. Distance from the center of the rotating frame to the bottom of the test cup: 45mm

3. Rotation speed

40±2)r/min

40±2)r/min4. Time control range

0 ~ 9999)min

0 ~ 9999)min5. Time control error: ≤±5s

6. Temperature control range: room temperature ~ 99.9℃;

7. Temperature control error: ≤±2℃

8. Heating method: electric heating

9. Power supply: AC380V±10% 50Hz 9kW

10. Overall size

930×690×840)mm

930×690×840)mm11. Weight: 170kg

-

YYPL-6C Handsheet Former(RAPID-KOETHEN)

Our this hand sheet former is applicable to research and experiments in papermaking research institutes and paper mills.

It forms pulp into a sample sheet, then puts the sample sheet on the water extractor for drying and then carries out the inspection of the physical intensity of the sample sheet to appraise the performance of the raw material of pulp and beating process specifications. Its technical indicators conform to the international & China specified standard for papermaking physical inspection equipment.

This former combines vacuum-sucking & forming, pressing, vacuum-drying into one machine, and all-electric control.